Comminution is a crucial step in the processing of mined materials. It involves the reduction of the particle size of the ore, which is typically achieved through crushing and grinding operations. The comminution design in a mine processing plant should be carefully planned to optimize the efficiency of the process while minimizing energy consumption and wear on equipment. Here is a general outline for designing a comminution circuit:

Ore Characterization

Ore characterization is a critical step in the mining and mineral processing industry. It involves the detailed analysis and understanding of the physical, chemical, and mineralogical properties of ore samples. This information is crucial for designing an efficient and cost-effective processing plant. Here’s a detailed breakdown of ore characterization:

- Sampling:

- Obtain representative samples from different locations within the ore deposit. These samples should be taken at various depths, orientations, and geological structures to capture the variability of the ore body.

- Sample Preparation:

- Crush larger samples to a size suitable for laboratory testing. This ensures that the characteristics measured are representative of the entire sample.

- Physical Properties:

- Particle Size Distribution:

- Analyze the size distribution of the ore particles. This information is essential for designing crushing and grinding circuits.

- Density and Porosity:

- Measure the density and porosity of the ore. This helps in determining the volume of material in the deposit.

- Particle Size Distribution:

- Mineralogical Analysis:

- Mineral Identification:

- Use techniques like X-ray diffraction (XRD) and scanning electron microscopy (SEM) to identify the minerals present in the ore. This information is crucial for understanding the mineral composition and its impact on processing.

- Mineral Liberation:

- Evaluate the degree to which valuable minerals are liberated from the gangue (waste) minerals. This affects the efficiency of downstream processes like flotation and leaching.

- Mineral Identification:

- Chemical Analysis:

- Elemental Composition:

- Determine the concentrations of key elements in the ore. This information is vital for designing processes like smelting, leaching, or flotation.

- Presence of Impurities:

- Identify any impurities or deleterious elements that may affect downstream processes or the quality of the final product.

- Elemental Composition:

- Geotechnical Properties:

- Rock Strength:

- Measure the strength properties of the ore, including compressive strength, tensile strength, and shear strength. This information is essential for mine planning and designing support systems.

- Rock Hardness:

- Determine the hardness of the ore material. This affects the selection of equipment for crushing and grinding.

- Rock Strength:

- Metallurgical Testing:

- Conduct metallurgical tests to evaluate the behaviour of the ore under different processing conditions. This includes tests for comminution, flotation, leaching, and other beneficiation processes.

- Hydrometallurgical Testing:

- If applicable, conduct tests to assess the behaviour of the ore in leaching or other hydrometallurgical processes.

- Environmental Considerations:

- Identify any environmental concerns related to the ore, such as the presence of hazardous elements or potential acid generation.

- Data Integration and Interpretation:

- Combine all the obtained data to create a comprehensive understanding of the ore body. This information forms the basis for process design and economic evaluations.

- Reporting:

- Compile the results of the characterization studies into a detailed report. This report serves as a critical reference for engineers and metallurgists involved in the design of the processing plant.

Ore characterization is an ongoing process, and additional tests may be conducted as more information becomes available during exploration and mine development. It’s also important to note that advances in analytical techniques may offer new insights into ore properties, leading to improved process design and optimization.

Crushing Stage

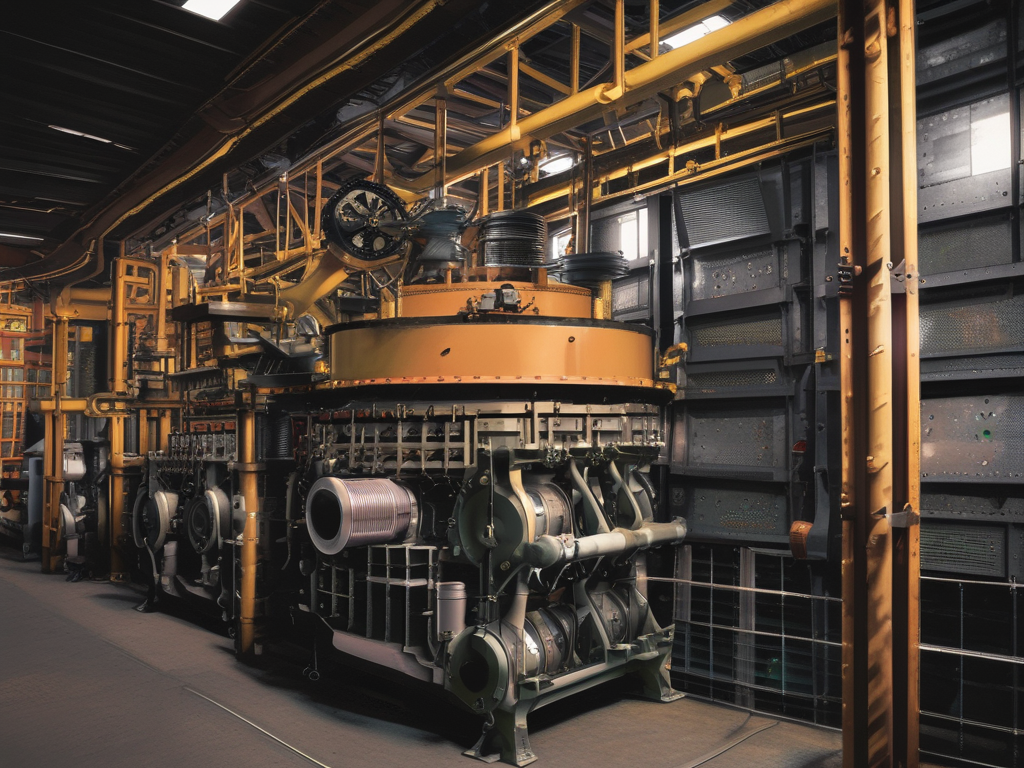

The crushing stage in mineral processing is a fundamental step that plays a crucial role in the overall efficiency of the processing plant. It involves reducing the size of the mined ore to a level where valuable minerals are liberated from the gangue material. Here’s a detailed breakdown of the crushing stage:

- Primary Crushing:

- Primary crushers are typically the first machines in the crushing process and are designed to handle large pieces of rock. Common types include jaw crushers, gyratory crushers, and impact crushers.

- Jaw Crushers:

- Use compressive force to crush the ore between a fixed jaw and a moving jaw. They are suitable for hard and abrasive materials.

- Gyratory Crushers:

- Consists of a conical-shaped head and a concave surface. Gyratory crushers are capable of handling very large feed sizes and are often used for high-capacity operations.

- Impact Crushers:

- Utilize impact rather than pressure to crush the material. They are used for softer materials or when a higher reduction ratio is required.

- Scalping:

- In some cases, a scalping screen may be used to remove fines or oversize material before it reaches the primary crusher. This helps to prevent blockages and improves the overall efficiency of the crushing circuit.

- Secondary Crushing:

- Secondary crushers are used to further reduce the size of the crushed material from the primary crusher. This is often done when a finer product size is required. Common secondary crushers include cone crushers and impact crushers.

- Cone Crushers:

- Operate by squeezing the material between an eccentrically gyrating cone and a concave. They are suitable for medium to hard materials.

- Impact Crushers (Secondary):

- Can be used for secondary crushing if the primary crusher has already produced a sufficiently small size. They are versatile and can handle a wide range of materials.

- Tertiary Crushing:

- Tertiary crushers are used to produce a further reduction in the size of the crushed material. This stage is typically employed when very fine particles are required for downstream processes. Tertiary crushers may include cone crushers, vertical shaft impactors (VSI), or high-pressure grinding rolls (HPGR).

- Crushing Circuit Design:

- Consider the arrangement of crushers in a circuit. Factors like feed size, product size requirements, and the characteristics of the ore should be taken into account.

- Operating Parameters:

- Optimize operating parameters such as crusher speed, closed-side setting, and throw to achieve the desired product size and production rate.

- Equipment Maintenance:

- Regular maintenance of crushers is crucial for preventing unexpected downtime and ensuring the longevity of the equipment.

- Safety Considerations:

- Implement safety protocols to protect personnel working around the crushing equipment. This may include proper guarding, isolation procedures, and training.

- Energy Efficiency:

- Implement strategies to optimize energy consumption during the crushing process, such as using variable speed drives and optimizing feed sizes.

- Control Systems:

- Utilize automation and control systems to monitor and adjust the operation of crushers for optimal performance.

The selection of crushers and the design of the crushing circuit depend on various factors including the type of ore, feed size, desired product size, and the overall plant layout. It’s important to conduct thorough ore characterization to ensure that the chosen crushing equipment is suitable for the specific characteristics of the ore.

Grinding Stage

The grinding stage in mineral processing is a crucial step where the size of the mined ore is further reduced to facilitate the liberation of valuable minerals from the gangue material. This process is typically carried out in grinding mills. Here’s a detailed breakdown of the grinding stage:

- Selection of Grinding Equipment:

- SAG Mills (Semi-Autogenous Grinding):

- Utilize ore itself as grinding media. They are typically used for coarse grinding and can handle both wet and dry ores.

- Ball Mills:

- Use steel balls as grinding media. They are commonly used for finer grinding and are suitable for both wet and dry grinding.

- Rod Mills:

- Use rods instead of balls as the grinding media. They are typically used for coarse grinding.

- SAG Mills (Semi-Autogenous Grinding):

- Grinding Media:

- Choose appropriate grinding media based on the hardness and abrasiveness of the ore. Common media materials include steel, ceramic, and high-chrome alloys.

- Grinding Circuit Configuration:

- Decide whether to use a single-stage or multi-stage grinding circuit based on the desired final particle size and the characteristics of the ore.

- Primary Grinding:

- In some cases, a primary grinding stage may be used to further reduce the size of the feed material before it enters the main grinding mill.

- Mill Liners:

- Select suitable liners for the grinding mill based on factors such as ore hardness, impact resistance, and wear properties.

- Mill Charge and Load Control:

- Optimize the mill charge to ensure efficient grinding. This involves managing the size distribution of grinding media and controlling the mill load.

- Grinding Media Wear:

- Monitor and manage the wear of grinding media to maintain grinding efficiency and minimize the need for frequent media replacement.

- Operating Parameters:

- Adjust key operating parameters like mill speed, feed rate, and slurry density to achieve the desired grinding performance.

- Classification:

- Implement classification systems (e.g., hydro cyclones, screens) to separate the ground material into different size fractions. This helps in controlling the size distribution of the final product.

- Recirculation and Circuits:

- Consider the use of recirculation in the grinding circuit to achieve the desired product size. Multiple stages of grinding may be employed to further reduce the particle size.

- Energy Efficiency:

- Implement strategies to optimize energy consumption during the grinding process, such as using high-efficiency motors and optimizing operating parameters.

- Liberation Assessment:

- Evaluate the degree to which valuable minerals are liberated from the gangue material. This information helps in optimizing the grinding process for efficient mineral recovery.

- Safety Considerations:

- Implement safety protocols to protect personnel working around the grinding equipment. This may include proper guarding, isolation procedures, and training.

- Control Systems:

- Utilize automation and control systems to monitor and adjust the operation of the grinding circuit for optimal performance.

The selection of grinding equipment and the design of the grinding circuit depends on various factors, including the type of ore, desired product size, and throughput requirements. It’s crucial to conduct thorough ore characterization to ensure that the chosen grinding equipment is suitable for the specific characteristics of the ore. Additionally, ongoing monitoring and optimization of the grinding process are essential for achieving optimal performance.

Classification and Screening

Classification and screening are essential processes in mineral processing that involve the separation of particles based on their size, shape, and other physical properties. These processes are crucial for controlling the size distribution of the final product and ensuring efficient operation of downstream equipment. Here’s a detailed breakdown of classification and screening:

- Screening Equipment:

- Vibrating Screens:

- Vibrating screens are widely used in mineral processing plants. They consist of a screen deck with openings of various sizes through which material passes. Vibrations cause the material to stratify, separating finer particles from coarser ones.

- Trommel Screens:

- Trommels are cylindrical drum-like screens that rotate. They are used for sizing and classifying material by tumbling it in a rotating drum, allowing smaller particles to fall through the screen.

- Static Screens:

- Static screens have fixed openings and are used for coarse screening applications, often at the beginning of a process.

- Grizzly Screens:

- Grizzly screens use parallel steel bars or rails to remove oversize material before it enters a primary crusher. They are especially useful in the primary crushing stage.

- Vibrating Screens:

- Classification Methods:

- Hydrocyclones:

- Hydrocyclones use centrifugal force to separate particles based on their size and density. They are commonly used in grinding circuits to classify slurry.

- Spiral Classifiers:

- Spiral classifiers are used to separate fine particles from coarse ones based on settling rates in a liquid medium.

- Screw Classifiers:

- Similar to spiral classifiers, screw classifiers use a rotating screw to transport and classify particles.

- Cyclones:

- Cyclones are used for dense medium separation or to classify particles in a slurry based on their density.

- Air Classifiers:

- Air classifiers use airflow to separate particles based on their size and density. They are used in dry processing operations.

- Hydrocyclones:

- Operating Parameters:

- Adjust factors like inclination, vibration frequency, and amplitude for vibrating screens to optimize screening efficiency.

- Control variables like cyclone pressure, feed density, and apex size for hydro cyclones to achieve the desired classification.

- Screen Media and Liners:

- Select appropriate screen media (e.g., woven wire, polyurethane, rubber) based on the material being processed and the desired separation efficiency.

- Regularly inspect and replace worn screen media and liners to maintain screening efficiency.

- Oversize and Undersize Handling:

- Implement systems to handle oversized and undersized material, ensuring that they are properly redirected for further processing or disposal.

- Dewatering Screens:

- Use dewatering screens to remove excess moisture from the material after the screening, especially in wet screening operations.

- Control Systems:

- Utilize automation and control systems to monitor and adjust the operation of screening and classification equipment for optimal performance.

- Maintenance and Safety:

- Implement regular maintenance schedules to inspect and service screening equipment, ensuring it operates at peak efficiency.

- Establish safety protocols for personnel working around screening and classification equipment. This may include proper guarding, isolation procedures, and training.

- Environmental Considerations:

- Implement dust control measures to mitigate environmental impacts, especially in dry screening operations.

- Product Quality Assurance:

- Monitor and test the final product to ensure it meets the specified size distribution and quality requirements.

The selection of screening and classification equipment and the design of the circuits depend on various factors, including the type of ore, desired product size distribution, and throughput requirements. It’s important to conduct thorough ore characterization to ensure that the chosen equipment is suitable for the specific characteristics of the ore. Additionally, ongoing monitoring and optimization of the screening and classification processes are crucial for achieving optimal performance.

Circuits and Flowsheets

Circuits and flowsheets are integral components of a mineral processing plant. They serve as blueprints for the arrangement and interaction of various unit operations to efficiently process the mined ore. Here’s a detailed breakdown of circuits and flowsheets in mineral processing:

- Definition:

- Circuit: A circuit in mineral processing refers to a combination of unit operations (e.g., crushing, grinding, classification) arranged in a specific sequence to achieve a particular objective, such as extracting valuable minerals from ore.

- Flowsheet: A flowsheet is a graphical representation that shows the sequence of unit operations and their interactions in a mineral processing plant. It includes the equipment used, the process flow, and key parameters.

- Process Objectives:

- Define the primary objectives of the process, such as maximizing metal recovery, minimizing energy consumption, or achieving a specific product quality.

- Unit Operations Integration:

- Arrange unit operations (e.g., crushing, grinding, flotation) in a logical sequence to achieve the desired process objectives.

- Material Handling and Transportation:

- Design systems for the handling, storage, and transportation of raw materials, intermediate products, and final products within the plant.

- Mass Balancing:

- Perform mass balancing to ensure that the flow of material into and out of each unit operation is accurately accounted for. This helps in optimizing the process and ensuring that valuable minerals are not lost.

- Water and Reagent Flows:

- Incorporate water and reagent systems into the flowsheet, indicating the sources, usage points, and recycling loops.

- Equipment Selection and Sizing:

- Choose appropriate equipment for each unit operation based on factors such as ore characteristics, throughput requirements, and product specifications.

- Control and Instrumentation:

- Integrate control systems and instrumentation to monitor and regulate process parameters. This includes sensors, actuators, and control loops.

- Piping and Instrumentation Diagram (P&ID):

- Create detailed P&ID diagrams that show the interconnection of equipment, pipelines, valves, and instrumentation in the plant.

- Heat and Energy Balances:

- Consider heat and energy balances to optimize the use of energy resources and minimize heat losses.

- Safety Considerations:

- Incorporate safety features and protocols into the design, including emergency shut-off systems, ventilation, and protective barriers.

- Environmental Considerations:

- Design systems to mitigate environmental impacts, such as dust control, water treatment, and emissions management.

- Testing and Validation:

- Conduct testing and validation of the flowsheet through pilot-scale or small-scale trials to ensure that it performs as expected.

- Flexibility and Expansion:

- Design the flowsheet with flexibility to accommodate variations in feed characteristics and future expansion of the plant.

- Documentation and Reporting:

- Document the flowsheet design, including equipment specifications, process parameters, and safety considerations, in a comprehensive report.

- Optimization and Continuous Improvement:

- Continuously monitor and analyze plant performance to identify opportunities for optimization and improvements in the flowsheet.

The design of circuits and flowsheets is a complex process that requires a multidisciplinary approach involving engineers, geologists, metallurgists, and other experts. It’s crucial to conduct thorough ore characterization and consider various factors like ore type, processing objectives, and economic constraints during the design process. Additionally, ongoing monitoring and adjustments are essential to maintain optimal performance.

Automation and Control

Automation and control systems play a vital role in modern mining and mineral processing operations. They enhance efficiency, safety, and productivity by automating various processes and providing real-time monitoring and control. Here’s a detailed breakdown of automation and control in mining and mineral processing:

- Process Automation:

- PLC (Programmable Logic Controller):

- PLCs are ruggedized computers used to automate electromechanical processes. They control machinery and equipment based on input signals and programming logic.

- DCS (Distributed Control System):

- DCS is a centralized control system that manages complex processes across different areas of a plant. It enables coordinated control of multiple units and processes.

- SCADA (Supervisory Control and Data Acquisition):

- SCADA systems provide real-time data acquisition and control capabilities. They monitor and control industrial processes, collect data, and generate alarms when parameters deviate from set points.

- HMI (Human-Machine Interface):

- HMIs are graphical user interfaces that allow operators to interact with the control system. They display process information, and alarms, and enable operators to input commands.

- Instrumentation:

- Sensors, transmitters, and detectors are used to measure parameters such as temperature, pressure, flow, level, and composition. This data is sent to the control system for monitoring and adjustment.

- PLC (Programmable Logic Controller):

- Process Optimization:

- Advanced Process Control (APC):

- APC strategies use mathematical models to optimize processes in real-time. They adjust process variables to maximize efficiency, throughput, and product quality.

- Machine Learning and AI:

- Implement machine learning algorithms and artificial intelligence to analyze data and make autonomous decisions for process optimization.

- Advanced Process Control (APC):

- Equipment Automation:

- Autonomous Vehicles:

- Utilize autonomous trucks, drills, and loaders for tasks like hauling, drilling, and loading, improving safety and productivity in mining operations.

- Remote Operation:

- Enable remote control of equipment in hazardous or hard-to-reach areas, reducing risks to operators.

- Autonomous Vehicles:

- Safety Systems:

- Emergency Shutdown Systems:

- Automatically shut down equipment or processes in emergency situations to prevent accidents or damage.

- Gas Detection Systems:

- Use sensors to detect the presence of hazardous gases and trigger alarms or safety measures.

- Personnel Tracking:

- Implement systems to monitor the location and safety of personnel within the plant, especially in critical or dangerous areas.

- Emergency Shutdown Systems:

- Environmental Monitoring:

- Emissions Control:

- Monitor and control emissions of pollutants to ensure compliance with environmental regulations.

- Water Management:

- Use sensors and controls to optimize water usage and treatment processes.

- Emissions Control:

- Data Management and Reporting:

- Historian Systems:

- Store and retrieve historical process data for analysis, troubleshooting, and reporting.

- Reporting and Analysis Tools:

- Generate reports on process performance, energy consumption, and environmental compliance.

- Historian Systems:

- Cybersecurity:

- Implement robust cybersecurity measures to protect control systems from unauthorized access and cyber threats.

- Integration and Interoperability:

- Ensure that automation systems are compatible with other plant systems, such as ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems).

- Training and Operator Competency:

- Provide comprehensive training programs to operators and maintenance personnel for effective use of automation systems.

- Lifecycle Management:

- Establish a plan for the maintenance, upgrade, and replacement of automation equipment to ensure its continued effectiveness.

Automation and control systems are critical components of modern mining and mineral processing operations. They enhance safety, efficiency, and productivity, leading to more sustainable and profitable operations. Thorough planning, implementation, and ongoing monitoring are essential for successful automation integration.

Energy Efficiency

Energy efficiency is a critical consideration in mining and mineral processing operations, as it directly impacts operating costs, environmental sustainability, and overall profitability. Here’s a detailed breakdown of energy efficiency measures in the mining and mineral processing industry:

- Energy Audits and Assessments:

- Conduct regular energy audits to identify areas of inefficiency and opportunities for improvement. These audits should encompass all aspects of the operation, including crushing, grinding, transportation, and beneficiation processes.

- Process Optimization:

- Utilize advanced process control (APC) systems, machine learning algorithms, and real-time data analysis to optimize process parameters. This can lead to more efficient use of energy resources.

- Equipment Selection and Sizing:

- Choose appropriately sized equipment based on the specific characteristics of the ore and the desired throughput. Undersized or oversized equipment can lead to inefficiencies and higher energy consumption.

- Comminution Efficiency:

- Focus on optimizing the comminution process (crushing and grinding) as it typically consumes a significant portion of the total energy in mineral processing. This includes selecting the right equipment and adjusting operating parameters.

- Material Handling and Conveying:

- Implement efficient material handling systems to minimize energy consumption during transportation. This includes using conveyors, belt scales, and automation to optimize material flow.

- Heat Recovery and Integration:

- Identify opportunities for heat recovery from processes with high thermal loads. This can involve using waste heat to preheat feed streams or for other applications within the plant.

- Energy-Efficient Equipment and Technology:

- Invest in energy-efficient equipment and technologies, such as high-efficiency motors, variable frequency drives (VFDs), and LED lighting.

- Alternative Energy Sources:

- Explore the use of renewable energy sources like solar, wind, or hydropower to supplement or replace conventional energy sources.

- Dewatering and Water Management:

- Optimize dewatering processes to reduce the energy required for water removal, especially in areas where large quantities of water are present.

- Process Integration and Heat Exchangers:

- Integrate processes to allow for the exchange of heat between different streams, reducing the need for additional heating or cooling.

- Waste Heat Recovery:

- Identify opportunities to capture and utilize waste heat generated during various processes within the plant.

- Energy-Efficient Lighting and HVAC Systems:

- Implement energy-efficient lighting systems and heating, ventilation, and air conditioning (HVAC) systems to reduce overall energy consumption.

- Training and Awareness:

- Provide training to personnel on energy-efficient practices and encourage a culture of energy conservation within the organization.

- Monitoring and Benchmarking:

- Install monitoring systems to track energy consumption in real time and compare performance against industry benchmarks.

- Lifecycle Assessment and Equipment Upgrades:

- Consider the entire lifecycle of equipment, including manufacturing, operation, and disposal, when making purchasing decisions. Upgrading older, less efficient equipment can lead to significant energy savings.

- Regulatory Compliance and Incentives:

- Stay informed about energy-related regulations and incentives provided by government agencies or industry associations. Compliance with energy efficiency standards can lead to cost savings and regulatory compliance.

Implementing energy efficiency measures in mining and mineral processing operations not only reduces operational costs but also contributes to environmental sustainability. It’s important to continually monitor and evaluate energy usage to identify additional opportunities for improvement.

Liner and Media Selection

Liner and media selection is a critical aspect of mineral processing operations, especially in comminution (crushing and grinding) circuits. Choosing the right liners and grinding media can significantly impact the efficiency, throughput, and wear characteristics of the equipment. Here’s a detailed breakdown of liner and media selection:

- Liner Selection:

- Mill Type and Size:

- Consider the type and size of the mill when selecting liners. Different types of mills (e.g., ball mills, and SAG mills) have specific liner requirements.

- Material of Construction:

- Choose liner materials based on factors such as ore hardness, abrasiveness, and corrosion resistance. Common liner materials include rubber, steel, composite, and ceramic.

- Liner Profile and Configuration:

- Select liner profiles and configurations (e.g., wave, grid, smooth) based on the specific grinding application and desired grinding action.

- Lifter Bars:

- Determine the shape and size of lifter bars to optimize the lifting and impact forces within the mill for efficient grinding.

- Maintenance and Installation Considerations:

- Evaluate ease of installation and maintenance when selecting liner materials and designs. Quick and easy liner replacement can reduce downtime.

- Mill Type and Size:

- Grinding Media Selection:

- Material Composition:

- Choose grinding media materials based on factors such as ore hardness, abrasiveness, and wear resistance. Common materials include steel, ceramic, and high-chrome alloys.

- Size and Shape:

- Select the size and shape of grinding media to achieve the desired level of comminution. Larger media may be used for coarse grinding, while smaller media is suitable for finer grinding.

- Media Density:

- Consider the density of the grinding media. High-density media can provide more energy for grinding, but lower-density media may reduce wear on equipment.

- Media Hardness:

- Evaluate the hardness of the media in relation to the hardness of the ore. Media that is too hard may lead to excessive wear on the mill, while media that is too soft may be less effective for grinding.

- Media Wear Rates:

- Understand the wear rates of different media materials to estimate maintenance and replacement schedules.

- Media Contamination:

- Consider the potential for media contamination and select materials that are compatible with the processing environment.

- Material Composition:

- Recycling and Replenishment:

- Implement systems for recycling and replenishing grinding media to maintain optimal grinding efficiency and minimize costs.

- Testing and Monitoring:

- Conduct regular tests to monitor the wear rates of liners and grinding media. This information can be used to schedule maintenance and replacement.

- Liner and Media Suppliers:

- Establish relationships with reputable suppliers who can provide high-quality liners and grinding media tailored to the specific requirements of the operation.

- Cost Considerations:

- Balance the initial cost of liners and media with their expected lifespan and impact on overall processing efficiency.

- Simulation and Modeling:

- Utilize computer simulations and modelling tools to predict the performance of different liner and media configurations.

- Safety and Environmental Considerations:

- Consider any safety or environmental regulations related to the selection and disposal of liners and grinding media.

Optimizing liner and media selection is crucial for maximizing the efficiency and cost-effectiveness of comminution processes. It’s important to conduct thorough ore characterization and performance testing to ensure that the chosen liners and media are well-suited to the specific characteristics of the ore and the operating conditions.

Maintenance and Wear Management

Maintenance and wear management are critical aspects of ensuring the smooth operation and longevity of equipment in mining and mineral processing operations. Proper maintenance practices help prevent unexpected downtime, reduce repair costs, and extend the lifespan of equipment. Here’s a detailed breakdown of maintenance and wear management:

- Routine Inspections:

- Conduct regular visual inspections of equipment to identify any signs of wear, damage, or potential issues. This includes checking for loose bolts, leaks, unusual noises, and visual wear indicators.

- Scheduled Maintenance:

- Establish a comprehensive maintenance schedule that includes routine tasks such as lubrication, belt tensioning, and component replacement. Follow manufacturer recommendations for maintenance intervals.

- Preventive Maintenance Programs:

- Implement preventive maintenance programs that include systematic checks, adjustments, and replacements to prevent breakdowns and extend equipment life.

- Condition Monitoring:

- Use advanced monitoring techniques (e.g., vibration analysis, thermography, oil analysis) to assess the condition of critical components. This allows for proactive maintenance before major failures occur.

- Wear Parts Inventory:

- Maintain an inventory of critical wear parts, such as liners, belts, and bearings, to ensure timely replacement when needed.

- Training and Skills Development:

- Provide training for maintenance personnel to ensure they have the necessary skills and knowledge to perform maintenance tasks effectively and safely.

- Wear-resistant Materials:

- Use high-quality wear-resistant materials for components that experience high levels of abrasion or impact. This includes liners, conveyor belts, and other high-wear parts.

- Predictive Maintenance:

- Utilize predictive maintenance techniques, such as condition-based monitoring and predictive analytics, to anticipate and address potential issues before they lead to equipment failure.

- Reliability-centered Maintenance (RCM):

- Implement RCM methodologies to prioritize maintenance activities based on criticality and potential impact on operations.

- Root Cause Analysis:

- Conduct thorough investigations to identify the root causes of equipment failures. This helps prevent similar issues from occurring in the future.

- Component Rebuilding and Refurbishment:

- Consider rebuilding or refurbishing components when feasible, rather than outright replacement. This can be a cost-effective way to extend the life of critical parts.

- Alignment and Balancing:

- Ensure proper alignment and balancing of rotating equipment to prevent premature wear and reduce the risk of catastrophic failures.

- Equipment Overhaul and Upgrades:

- Plan for periodic overhauls and consider upgrades or retrofits to improve the performance and efficiency of equipment.

- Warranty and Service Contracts:

- Consider purchasing warranties or service contracts from equipment suppliers to ensure access to expert support and timely replacement of faulty components.

- Recordkeeping and Documentation:

- Maintain detailed records of maintenance activities, including dates, tasks performed, and any issues identified. This information can be invaluable for tracking equipment performance over time.

- Safety Considerations:

- Prioritize safety during maintenance activities by following established procedures, using appropriate personal protective equipment (PPE), and conducting risk assessments.

Proactive maintenance and wear management practices are essential for maximizing equipment reliability and minimizing operational disruptions. It’s important to tailor maintenance strategies to the specific requirements of each piece of equipment and to regularly review and adjust maintenance plans based on performance data and changing operational conditions.

Monitoring and Optimization

Monitoring and optimization are crucial processes in mining and mineral processing operations. They involve continuously assessing various parameters and performance indicators to identify opportunities for improvement and ensure efficient and profitable operation. Here’s a detailed breakdown of monitoring and optimization:

- Real-time Monitoring:

- Implement sensors, instrumentation, and control systems to continuously monitor key parameters such as temperature, pressure, flow rates, and material levels.

- Data Acquisition and Analysis:

- Collect and analyze data from various sensors and monitoring systems to gain insights into the performance of equipment and processes.

- Advanced Analytics and Data Modeling:

- Utilize advanced analytics, machine learning algorithms, and mathematical models to predict trends, detect anomalies, and optimize processes based on historical data.

- Process Control and Automation:

- Employ control systems to automatically adjust process parameters in real-time, optimizing for factors like throughput, energy consumption, and product quality.

- Energy Efficiency:

- Monitor energy consumption and implement strategies to optimize energy usage, such as adjusting equipment settings or implementing energy-saving technologies.

- Waste Management and Recycling:

- Monitor waste streams and implement recycling programs to minimize environmental impact and recover valuable resources.

- Quality Control:

- Implement quality control measures to ensure that final products meet specified quality standards. This may include sampling and testing procedures.

- Process Stability and Reliability:

- Monitor the stability and reliability of processes to identify and address issues that may lead to unexpected downtime or reduced efficiency.

- Maintenance Optimization:

- Use performance data and condition monitoring to schedule maintenance activities at optimal intervals, reducing both planned and unplanned downtime.

- Throughput and Capacity Optimization:

- Continuously assess and adjust equipment settings and operating parameters to maximize throughput and capacity while maintaining product quality.

- Material Flow Optimization:

- Analyze material flow through the processing plant to identify and address bottlenecks or inefficiencies.

- Water and Resource Management:

- Monitor and optimize water usage, as well as the consumption of other resources like chemicals and reagents.

- Environmental Compliance:

- Monitor and track environmental performance to ensure compliance with regulatory requirements and reduce the impact of operations on the environment.

- Safety Monitoring:

- Implement safety monitoring systems to detect and respond to potential hazards in real-time, ensuring the well-being of personnel.

- Cost Optimization:

- Continuously assess operational costs and identify opportunities for cost reduction, such as optimizing resource usage or implementing more efficient processes.

- Continuous Improvement Culture:

- Foster a culture of continuous improvement among staff by encouraging them to identify and implement optimization opportunities.

- Feedback Loops and Reporting:

- Establish feedback loops to communicate optimization results and lessons learned to relevant stakeholders, ensuring that improvements are effectively implemented.

Regularly reviewing and adjusting operational strategies based on monitoring and optimization efforts can lead to significant improvements in efficiency, productivity, and profitability in mining and mineral processing operations. It’s crucial to involve cross-functional teams and utilize advanced technologies to maximize the benefits of these processes.

Discover more from AllMinings

Subscribe to get the latest posts sent to your email.