Gold processing involves several stages, each designed to extract the highest possible yield of gold from the ore. Below is a general overview of the typical process:

Crushing

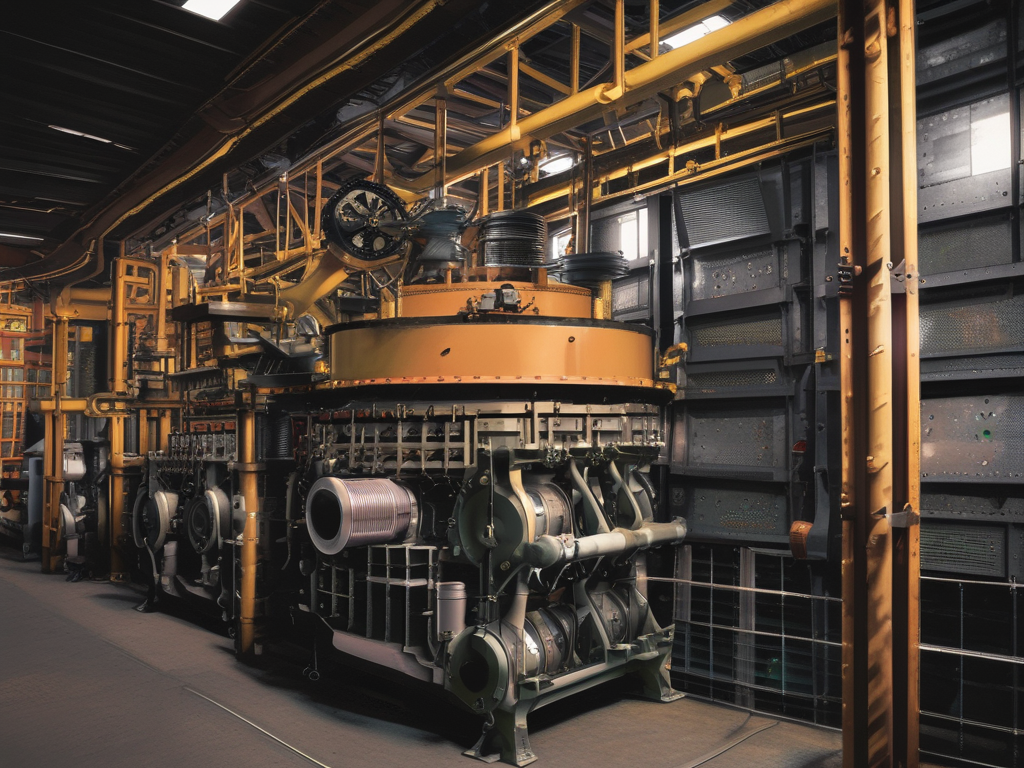

Crushing is a mechanical process that aims to reduce the size of a solid material, like ore, into smaller pieces. This is often a necessary step in various industries, including mining, construction, and recycling. Here’s an overview of the crushing process:

- Material Selection:

- The material to be crushed is chosen based on its composition and intended use. This can range from rocks and minerals in mining operations to concrete and asphalt in construction and demolition activities.

- Feeding:

- The material is fed into the crusher. This can be done manually, using a conveyor belt, or by other mechanical means depending on the setup.

- Primary Crushing:

- In many cases, the initial crushing is done in a primary crusher. This crusher reduces the size of the material significantly. Jaw crushers, gyratory crushers, and impact crushers are common types of primary crushers.

- Secondary Crushing:

- If further reduction is required, the crushed material may go through secondary crushing. This is typically done with a different type of crusher that imparts more force or pressure to the material. Cone crushers and impact crushers are often used for secondary crushing.

- Screening:

- After the material has been crushed to the desired size, it may go through a screening process to separate different sizes or grades. This is particularly important in industries like mining where different grades of ore are needed.

- Recirculation (if applicable):

- In some operations, material that doesn’t meet the desired size specification in the first pass through the crusher may be recirculated for further crushing.

- Final Sizing:

- Depending on the application, the material might go through additional crushing stages to achieve the final desired size. This is especially common in industries like aggregate production and mining.

- Output:

- The crushed material is now ready for further processing or use in its intended application. This could involve additional processing steps like grinding, flotation (in the case of minerals), or mixing (in the case of construction materials).

- Safety Measures:

- Safety is of paramount importance in crushing operations. Protective equipment, training, and protocols are followed to ensure the safety of operators and those working around the crushing equipment.

- Maintenance and Inspection:

- Regular maintenance and inspection of the crushing equipment are crucial for its efficient and safe operation. This includes tasks like lubrication, replacement of worn parts, and ensuring all safety features are functioning properly.

It’s important to note that the specific equipment and processes used in crushing can vary widely depending on the industry and the type of material being processed. For example, the equipment used for crushing rocks in mining operations may differ significantly from that used in recycling facilities. Always refer to industry-specific guidelines and consult with experts for the most accurate and up-to-date information.

Grinding

Grinding is a mechanical process used to reduce the size of solid materials into smaller, more manageable particles. It’s a crucial step in various industries including mining, manufacturing, and food processing. Here’s an overview of the grinding process:

- Material Selection:

- The material chosen for grinding depends on its composition and intended use. This can range from minerals and ores in mining to grains and spices in food processing.

- Preparation:

- Before the grinding process begins, the material is often prepared. This might involve drying, cleaning, or pre-processing to remove impurities or moisture.

- Loading:

- The prepared material is fed into the grinding machine. This can be done manually or using conveyors, hoppers, or other feeding mechanisms, depending on the scale of the operation.

- Selection of Grinding Equipment:

- The type of grinding equipment used depends on the material and the desired particle size. Common types of grinding equipment include ball mills, rod mills, hammer mills, and grinders with specialized surfaces like grinding wheels.

- Grinding Process:

- The grinding machine exerts a mechanical force on the material, which causes it to break apart or be reduced in size. This is typically achieved through impact, compression, and attrition forces.

- Classification (if applicable):

- After the initial grinding, the material may go through a classification process to separate out different particle sizes. This is common in industries requiring a specific range of particle sizes.

- Recirculation (if applicable):

- In some grinding operations, material that doesn’t meet the desired size specification in the first pass through the grinder may be recirculated for further grinding.

- Final Sizing:

- Depending on the application, the material might go through additional stages of grinding to achieve the final desired size. This is especially common in industries like mining and manufacturing.

- Quality Control:

- Throughout the grinding process, quality control measures are implemented to ensure that the final product meets industry standards and customer specifications.

- Safety Measures:

- Safety is paramount in grinding operations. Operators are trained to use the equipment safely, and protective measures such as guards and safety protocols are followed to prevent accidents.

- Maintenance and Inspection:

- Regular maintenance and inspection of the grinding equipment are crucial for its efficient and safe operation. This includes tasks like lubrication, replacement of worn parts, and ensuring all safety features are functioning properly.

It’s important to note that the specific equipment and processes used in grinding can vary widely depending on the industry and the type of material being processed. Always refer to industry-specific guidelines and consult with experts for the most accurate and up-to-date information.

Gravity Separation

Gravity separation is a method used to separate two or more components of a mixture based on differences in density. This process is widely used in various industries, including mining, mineral processing, and recycling. Here’s an overview of the gravity separation process:

- Material Preparation:

- The mixture to be separated is typically in the form of a slurry, which is a combination of solid particles suspended in a liquid. This slurry is often prepared by grinding or crushing the raw material to a suitable size.

- Introduction to the Separator:

- The slurry is introduced into a vessel or equipment specifically designed for gravity separation. Common equipment used for gravity separation includes jigs, shaking tables, spirals, and centrifugal concentrators.

- Settling and Stratification:

- Once introduced into the separator, the slurry experiences a change in flow dynamics. Heavier particles tend to settle more quickly, while lighter particles remain suspended or settle at a slower rate.

- Separation Mechanism:

- The separator is designed to exploit the differences in density between the components. Heavier particles are subjected to greater gravitational forces and tend to migrate towards the bottom of the vessel, while lighter particles move upwards.

- Adjustment and Control:

- Various factors can be adjusted to optimize the separation process, including the angle of the separator, the flow rate of the slurry, and the amplitude or frequency of the shaking or vibration (if applicable).

- Collection and Discharge:

- The separated components are collected or discharged from different points within the separator. Heavier particles, often referred to as concentrates, are typically collected from the bottom, while lighter particles, known as tailings, are collected from the top.

- Recirculation (if applicable):

- In some cases, particularly when fine particles are involved, the process may involve recirculating some of the material for further separation.

- Final Processing:

- Depending on the industry and specific application, the separated components may undergo further processing steps. For example, in mineral processing, the concentrate may be further processed through methods like smelting or leaching.

- Quality Control:

- Throughout the process, quality control measures are implemented to ensure that the final products meet industry standards and customer specifications.

- Safety Measures:

- Safety is a critical consideration in gravity separation operations. Operators are trained to use the equipment safely, and protective measures are in place to prevent accidents.

Gravity separation is particularly effective for separating minerals with different densities, making it a common method in mining operations to extract valuable ores like gold, tin, and diamonds. It’s worth noting that specific equipment and techniques can vary depending on the application and the characteristics of the materials being processed. Always refer to industry-specific guidelines and consult with experts for the most accurate and up-to-date information.

Flotation

Flotation is a widely used method for separating valuable minerals from non-valuable minerals in ores. It relies on the differences in the surface properties of minerals, making it especially effective for processing complex ores containing multiple minerals. Here’s an overview of the flotation process:

- Preparation of Ore:

- The ore is first crushed and ground into a fine powder. This increases the surface area for the subsequent flotation process.

- Creation of a Slurry:

- The ground ore is mixed with water to create a slurry. This slurry typically contains finely ground particles of both valuable and non-valuable minerals.

- Addition of Reagents:

- Chemical reagents are added to the slurry. These reagents may include collectors, frothers, modifiers, and pH regulators. Collectors enhance the hydrophobicity (water-repellent) properties of valuable minerals, while frothers create a stable froth on the surface of the flotation cell. Modifiers can change the surface properties of minerals to improve selectivity.

- Agitation and Aeration:

- The slurry is introduced into a flotation cell or tank. Agitators and aerators agitate the mixture, creating bubbles. These bubbles attach to the hydrophobic particles (typically valuable minerals), causing them to rise to the surface.

- Froth Formation:

- As air is introduced into the slurry, froth forms at the top of the cell. This froth is rich in valuable mineral particles.

- Recovery:

- The froth containing the valuable minerals overflows from the flotation cell, while the non-valuable minerals remain in the slurry.

- Skimming:

- The froth is typically skimmed off and collected in troughs or launderers. This collected froth, which is called the concentrate, contains a high concentration of the valuable mineral.

- Tailings:

- The remaining slurry, which now contains mostly non-valuable minerals, is referred to as tailings. These are often discharged from the flotation process.

- Further Processing:

- The concentrate collected from the flotation process may undergo further processing steps depending on the specific industry. For example, in mineral processing, further steps like smelting or leaching may be employed.

- Quality Control:

- Throughout the process, quality control measures are implemented to ensure that the final products meet industry standards and customer specifications.

- Safety Measures:

- Safety is paramount in flotation operations. Operators are trained to use the equipment safely, and protective measures are in place to prevent accidents.

Flotation is widely used in the mining industry to extract valuable minerals such as copper, lead, zinc, and gold. It’s also used in other industries like wastewater treatment, where it’s employed to separate and recover suspended solids.

Keep in mind that specific reagents and techniques used in flotation can vary depending on the type of ore and the desired end products. Always consult with experts or refer to industry-specific guidelines for the most accurate and up-to-date information.

Cyanidation

Cyanidation is a method used in the extraction of gold from its ore. It is a chemical process that relies on the ability of gold to form a soluble cyanide-gold complex, allowing it to be easily separated from surrounding minerals. Here is an overview of the cyanidation process:

- Crushing and Grinding:

- Before cyanidation, the gold ore is typically crushed and ground to a fine powder. This increases the surface area for the subsequent chemical reactions.

- Preparation of the Ore:

- The finely ground ore is mixed with water to create a slurry. This slurry typically contains both gold particles and other minerals.

- Pre-treatment (if necessary):

- In some cases, the ore may require pre-treatment steps such as roasting, bio-oxidation, or pressure oxidation to make the gold more accessible for cyanide leaching.

- Leaching:

- A dilute solution of sodium cyanide (NaCN) is added to the slurry. The cyanide ions react with the gold in the ore to form a soluble complex known as a “gold-cyanide complex” (Au(CN)2-).

- Adsorption:

- The gold-cyanide complex is then adsorbed onto activated carbon, typically in a process known as carbon-in-pulp (CIP) or carbon-in-leach (CIL). This is done by passing the slurry through tanks or columns filled with activated carbon.

- Separation and Recovery:

- The slurry is then passed over screens to separate the activated carbon, which contains the gold-cyanide complex, from the rest of the slurry.

- Elution and Electro-Winning:

- The loaded carbon, now containing the gold, is subjected to elution. This involves passing a hot caustic-cyanide solution through the carbon, which removes the gold from the carbon.

- The gold is then recovered from the eluate (the solution containing the gold) using electrowinning, a process where an electric current is passed through the solution causing the gold to plate onto a cathode.

- Refining:

- The gold obtained from the above steps may still contain impurities. Refining is done to remove these impurities and obtain high-purity gold.

- Final Processing:

- The refined gold may be poured into moulds to form bars or further processed into other shapes or products, depending on market demand.

- Quality Control:

- Throughout the process, quality control measures are implemented to ensure that the gold produced meets industry standards and customer specifications.

- Environmental and Safety Considerations:

- Cyanidation is associated with environmental and safety concerns, so modern processing plants implement various measures to minimize environmental impact and ensure the safety of workers.

It’s crucial to note that safety and environmental regulations are integral parts of modern gold processing using cyanidation. These facilities implement various measures to minimize environmental impact and ensure the safety of workers. Always consult with experts or refer to up-to-date resources for the latest practices in cyanidation.

Elution and Electro-Winning

Elution and electro-winning are critical processes in gold extraction and refining. They are typically used after the cyanidation process to recover gold from loaded carbon. Here’s an overview of each process:

Elution:

- Introduction of Loaded Carbon:

- Loaded carbon, which contains the gold-cyanide complex, is introduced into an elution column or vessel. This carbon has previously been used in the cyanidation process and now carries a significant amount of gold.

- Elution with Hot Solution:

- A hot caustic-cyanide solution is passed through the column containing the loaded carbon. This solution serves to “strip” or remove the gold from the carbon particles.

- Desorption of Gold:

- The hot solution causes the gold-cyanide complex to break down, releasing the gold ions from the carbon surface. The gold then goes into solution as part of the eluate.

- Electrowinning (Optional):

- In some cases, the eluate may be sent directly to the electro-winning process to recover gold. This is often the case when high-purity gold is desired.

- Regeneration of Carbon:

- After elution, the “stripped” carbon is typically regenerated for reuse in the adsorption process. This involves heating the carbon to high temperatures to remove any remaining gold and impurities.

Electro-Winning:

- Introduction of Eluate:

- The eluate, which contains the dissolved gold, is introduced into an electro-winning cell or tank.

- Electrolysis Process:

- The electro-winning cell contains a cathode (usually made of stainless steel or other inert material) and an anode (usually made of lead or other inert material). The cathode is connected to the negative terminal of a power supply, while the anode is connected to the positive terminal.

- When an electric current is applied, gold ions from the eluate migrate towards the cathode and plate onto its surface. This is because gold ions have a positive charge and are attracted to the negatively charged cathode.

- Formation of Gold Deposits:

- As gold ions accumulate on the cathode, they form a layer of solid gold. This layer can be periodically removed.

- Collection of Gold Deposits:

- The gold deposits collected on the cathode are periodically removed and further processed to obtain high-purity gold.

- Recirculation of Electrolyte:

- The electrolyte, which now contains fewer gold ions, is typically recirculated back into the elution process for further use.

- Quality Control:

- Throughout the process, quality control measures are implemented to ensure that the gold produced meets industry standards and customer specifications.

Elution and electro-winning are crucial steps in the overall gold extraction and refining process, and they play a significant role in producing high-quality gold for various industries.

Smelting

Smelting is a process used to extract metals from their ores, typically through the application of heat and a reducing agent. It’s a fundamental step in the production of many metals, including gold, silver, copper, and iron. Here’s an overview of the smelting process:

- Ore Preparation:

- The process begins with the collection and preparation of the raw ore. The ore is usually crushed and ground into a fine powder to increase its surface area.

- Roasting (if necessary):

- In some cases, especially for sulphide ores, roasting may be employed. Roasting involves heating the ore in the presence of air or oxygen to remove sulphur or other volatile impurities.

- Melting:

- The prepared ore or concentrate is heated in a furnace to a high temperature. This melts the metal content of the ore, allowing it to separate from the impurities.

- Addition of Fluxes:

- Fluxes, such as limestone or silica, are added to the furnace. These materials serve several purposes:

- They react with impurities, forming slag that can be easily separated from the molten metal.

- They help control the viscosity of the slag, aiding in the separation process.

- They protect the furnace lining from erosion.

- Fluxes, such as limestone or silica, are added to the furnace. These materials serve several purposes:

- Separation of Slag and Metal:

- As the metal melts, it sinks to the bottom of the furnace due to its higher density. Meanwhile, the impurities react with the fluxes to form a molten slag that floats on top of the metal.

- Tapping:

- The molten metal is periodically tapped or poured out of the furnace through a tap hole at the bottom. This is done to separate it from the slag.

- Casting:

- The molten metal is then poured into moulds to form ingots or other shapes, depending on the desired end product.

- Cooling and Solidification:

- Once cast, the metal cools and solidifies, taking on the shape of the mould.

- Further Processing (if necessary):

- Depending on the industry and the specific metal being produced, additional processing steps may be required. For example, refining processes may be employed to further purify the metal.

- Quality Control:

- Throughout the process, quality control measures are implemented to ensure that the final product meets industry standards and customer specifications.

- Environmental and Safety Considerations:

- Smelting operations often involve high temperatures and potentially hazardous materials. As a result, strict safety and environmental regulations are followed to protect workers and the environment.

Smelting is a crucial step in the production of metals and alloys, and it’s employed in various industries including metallurgy, mining, and manufacturing. It’s important to note that specific smelting techniques and parameters can vary depending on the type of ore and the desired end product. Always refer to industry-specific guidelines and consult with experts for the most accurate and up-to-date information.

Refining

Refining is the process of purifying a substance, typically a metal, to remove impurities and obtain a high degree of purity. This process is crucial for industries that require metals with specific qualities and low levels of impurities. Here’s an overview of the refining process:

- Introduction of Impure Material:

- The material to be refined, often referred to as “done” in the case of gold, is introduced into the refining process. This material contains the desired metal along with impurities.

- Sampling and Analysis:

- A representative sample of the impure material is taken for analysis. This is important for determining the composition and identifying impurities that need to be removed.

- Melting or Dissolution:

- The impure material is melted or dissolved to make it more amenable to further processing. The specific method used depends on the nature of the material. For example, gold dore is typically melted.

- Removal of Impurities:

- Different methods are employed to remove specific impurities. Common techniques include:

- Electrolysis: Used for metals like copper, where impurities are selectively dissolved into an electrolyte.

- Chemical Precipitation: Adding chemicals to the molten metal to form insoluble compounds with impurities.

- Solvent Extraction: Using solvents to selectively dissolve impurities.

- Vacuum Distillation: Employed for refining high-boiling metals like tantalum or niobium.

- Different methods are employed to remove specific impurities. Common techniques include:

- Filtration or Settling:

- After impurities are treated, the remaining material may be subjected to filtration or settling to separate out any remaining solids or precipitates.

- Casting or Solidification:

- The refined material may be cast into specific shapes, such as ingots, bars, or other forms, depending on its intended use.

- Quality Testing and Analysis:

- The refined material undergoes rigorous testing to ensure it meets industry standards and customer specifications. This may include assays, chemical analyses, and other quality control measures.

- Final Inspection:

- The refined product is visually inspected for any defects or irregularities that may have occurred during the refining process.

- Packaging and Storage:

- The refined material is packaged and stored in a manner appropriate for its type and intended use.

- Environmental Considerations:

- Refining processes can generate waste products and emissions. Modern refining facilities implement various measures to minimize environmental impact and ensure compliance with environmental regulations.

- Safety Measures:

- Safety is paramount in refining operations. Operators are trained to use the equipment safely, and protective measures are in place to prevent accidents.

Refining is a crucial step in the production of high-quality metals for various industries, including electronics, aerospace, and medical devices. Specific refining techniques and parameters can vary widely depending on the type of material and the desired end product. Always refer to industry-specific guidelines and consult with experts for the most accurate and up-to-date information.

Pouring and Forming

“Pouring and Forming” refers to the final steps in the processing of metals, particularly after refining or smelting, where the purified metal is shaped into a specific form for its intended use. Here’s an overview of these processes:

Pouring:

- Molten Metal Preparation:

- Prior to pouring, the metal must be in a molten state. This is typically achieved through smelting, refining, or melting in a furnace.

- Crucible or Furnace:

- The molten metal is contained within a vessel, often made of refractory materials like graphite or ceramics. This vessel is called a crucible or furnace.

- Casting Molds:

- Molds are prepared based on the desired final shape of the metal. Molds can be made of various materials like sand, metal, or ceramics, depending on factors like metal type and intricacy of the design.

- Pouring Process:

- The molten metal is carefully poured from the crucible into the prepared mould. This process requires precision to ensure the metal flows into all areas of the mould.

- Cooling and Solidification:

- As the molten metal fills the mould, it begins to cool and solidify. The cooling rate can be controlled to achieve specific characteristics in the final product.

Forming:

- Removal from the Mold:

- After the metal has sufficiently cooled and solidified, it is removed from the mould. Depending on the type of mould, this may involve breaking the mould, using specialized equipment, or employing release agents.

- Post-Processing (if necessary):

- The newly formed metal may undergo additional processing steps such as machining, grinding, or polishing to achieve the desired surface finish and dimensions.

- Quality Inspection:

- The formed metal is inspected for any defects or irregularities that may have occurred during the pouring and forming process. This includes dimensional accuracy and surface finish.

- Additional Processing (if necessary):

- Depending on the industry and the specific requirements of the final product, the formed metal may undergo further processing steps. This could include heat treatment, coating, or other specialized treatments.

- Final Inspection:

- The formed metal is subjected to a final quality inspection to ensure it meets industry standards and customer specifications.

- Packaging and Storage:

- The final formed product is packaged and stored in a manner appropriate for its type and intended use.

- Environmental Considerations:

- Forming processes can generate waste products and emissions. Modern farming facilities implement various measures to minimize environmental impact and ensure compliance with environmental regulations.

- Safety Measures:

- Safety is of paramount importance in pouring and forming operations. Operators are trained to use the equipment safely, and protective measures are in place to prevent accidents.

Pouring and forming are crucial steps in the production of metal products, and they are employed in various industries including manufacturing, construction, and aerospace. Specific techniques and parameters can vary widely depending on the type of metal and the intended end product. Always refer to industry-specific guidelines and consult with experts for the most accurate and up-to-date information.

Quality Control

Quality control (QC) is a systematic process implemented to ensure that products or services meet specific standards and conform to customer requirements. It involves a series of checks, inspections, and tests throughout the production or service delivery process. Here is an overview of quality control:

- Establishment of Standards:

- The first step in quality control is setting clear and measurable standards or specifications for the product or service. These standards should be based on customer expectations, industry regulations, and company requirements.

- Documentation and Procedures:

- Quality control procedures, including testing methods, inspection protocols, and documentation requirements, are established. This provides a clear framework for conducting quality checks.

- Incoming Material Inspection:

- Raw materials or components are inspected upon arrival to ensure they meet the specified quality standards. This prevents the use of subpar materials in the production process.

- In-Process Inspections:

- Inspections are conducted at various stages of production to identify and rectify any defects or deviations from the established standards. This helps prevent the production of non-conforming products.

- Testing and Measurement:

- Various tests and measurements are performed to assess product attributes like dimensions, strength, durability, and other relevant characteristics. This may include destructive and non-destructive testing methods.

- Statistical Process Control (SPC):

- SPC involves the use of statistical techniques to monitor and control the production process. It helps identify trends, patterns, and variations in the manufacturing process that may impact product quality.

- Final Inspection:

- Once the product is completed, a final inspection is conducted to ensure it meets all specified quality standards before it is released to the customer.

- Documentation and Record Keeping:

- Detailed records of quality control activities, including test results, inspection reports, and any corrective actions taken, are maintained. This documentation provides a traceable history of each product.

- Root Cause Analysis:

- In the event of a quality issue, a root cause analysis is conducted to determine the underlying reason for the non-conformance. This helps identify corrective actions to prevent similar issues in the future.

- Corrective and Preventive Actions (CAPA):

- If a non-conformance is identified, corrective actions are implemented to address the immediate issue. Additionally, preventive actions are taken to ensure similar problems do not occur in the future.

- Feedback and Continuous Improvement:

- Customer feedback and data from quality control processes are used to drive continuous improvement initiatives. This includes refining processes, updating standards, and enhancing product design.

- Training and Education:

- Quality control personnel receive appropriate training to perform their duties effectively. This includes understanding testing methods, using inspection equipment, and interpreting results.

- Regulatory Compliance:

- Quality control processes ensure compliance with industry regulations and standards, as well as any legal requirements pertaining to the product or service.

Quality control is essential for ensuring that products or services consistently meet or exceed customer expectations. It helps build trust with customers, reduces the risk of defects or recalls, and ultimately leads to improved customer satisfaction and business success.

Discover more from AllMinings

Subscribe to get the latest posts sent to your email.