A mining crusher is a machine used to reduce large rocks into smaller pieces. Crushers are designed to handle a range of materials. It is from ores to coal and various minerals used in the mining industry. There are several types of crushers commonly used in mining operations:

Jaw Crusher

A jaw crusher is a primary crushing machine used in the mining and aggregate industries. It’s designed to crush large rocks into smaller, more manageable pieces. Here’s a detailed description of a typical jaw crusher:

Components of a Jaw Crusher:

- Fixed Jaw Plate: This is the static, immovable part of the jaw crusher that holds the crushing chamber in place. It provides structural support and is typically made of cast steel.

- Movable Jaw Plate: Also known as the swing jaw, this part moves back and forth, applying force to the material being crushed. It’s attached to an eccentric shaft that causes the reciprocating motion.

- Eccentric Shaft: This is a crucial component that transmits power from the motor to the movable jaw. It’s typically made of forged steel and rotates on heavy-duty bearings.

- Toggle Plate: The toggle plate is a safety mechanism designed to break in case of overloading. It connects the movable jaw to the toggle mechanism, allowing the jaw to pivot and apply pressure.

- Toggle Bearings: These are heavy-duty spherical roller bearings that support the eccentric shaft and allow it to rotate smoothly.

- Pitman: The pitman is a rugged steel casting that acts as a connecting link between the toggle plate and the movable jaw. It provides the oscillating motion needed for crushing.

- Flywheel: This is a large, heavy wheel attached to the eccentric shaft. It helps to maintain the momentum of the jaw crusher and provides additional crushing power during startup.

- Adjustment Wedge: The wedge is used to adjust the gap between the fixed and movable jaws, controlling the size of the crushed material.

How a Jaw Crusher Works:

- Feed Hopper: Rocks or ore are fed into the crusher through a hopper. The size of the material can vary, depending on the specific application.

- Crushing Chamber: The material enters the crushing chamber, where the movable jaw exerts force on it. The rock is crushed between the stationary and movable jaws.

- Discharge Opening: Once the material reaches the desired size, it exits through the discharge opening at the bottom of the crusher.

Types of Jaw Crushers:

- Single Toggle Jaw Crusher: In this type, the swing jaw is suspended on the eccentric shaft, which leads to a much more compact design than that of the double toggle jaw crusher. It’s also easier to manage and maintain.

- Double Toggle Jaw Crusher: This design has two swinging jaws that move back and forth. The primary difference is in the location of the eccentric shaft. These crushers tend to be more expensive but offer advantages in certain applications.

Applications:

Jaw crushers are primarily used for primary crushing in mining, quarrying, recycling, and construction industries. They’re capable of processing various types of materials, including hard rocks, ores, and recycled concrete.

It’s important to note that jaw crushers come in various sizes and capacities to accommodate different production requirements. Proper maintenance, such as regular lubrication and inspection of worn parts, is essential for optimal performance and longevity.

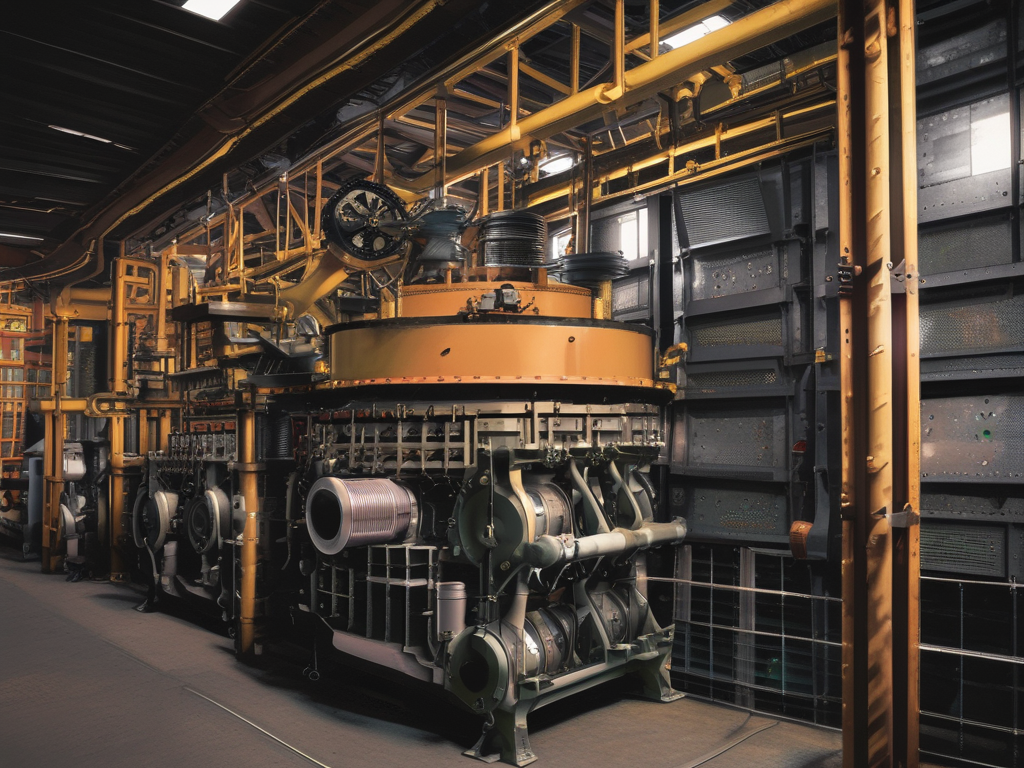

Gyratory Crusher

A gyratory crusher is a primary crusher used in the mining and ore processing industry. It is characterized by its large feed opening, which is designed to accept and process very large quantities of material. The gyratory crusher operates by crushing materials between the gyrating spindles mounted on an eccentrically-shaped central vertical spindle and the concave liners (often referred to as the mantle) positioned on the inside of the crushing chamber.

Here are the key components and workings of a typical gyratory crusher:

Components of a Gyratory Crusher:

- Mantle: This is the fixed concave surface that encases the crushing chamber. It’s shaped like an inverted cone and is often lined with wear-resistant materials.

- Concave Liners: The concave liners are the replaceable wear-resistant surfaces that line the inside of the crushing chamber. They are designed to protect the main frame of the crusher and maintain the proper crushing profile.

- Spider Arm Assembly: The spider arm assembly is a structural component that connects the main frame to the mantle. It’s equipped with a spider arm and a spider bushing, allowing the main shaft to move eccentrically.

- Main Shaft: The main shaft is the central vertical spindle that supports and transmits the rotating motion to the crushing head.

- Eccentric Assembly: This assembly comprises the eccentric shaft, eccentric bushing, and counterweight. It’s responsible for creating the gyrating motion of the main shaft.

- Gyrating Head: Also known as the crushing head, it is the large circular steelhead that moves eccentrically. It crushes the material against the concave liners.

- Dust Seal Ring: The dust seal ring is located between the mantle and the concave liners. It prevents dust and contaminants from entering the crusher.

- Hydraulic Cylinder: Some modern gyratory crushers are equipped with hydraulic cylinders that provide various functions, such as adjusting the crusher setting, tramp release, and clamping during maintenance.

How a Gyratory Crusher Works:

- Feed Hopper: Material is loaded into the crusher through the feed hopper.

- Crushing Chamber: The material is crushed as it enters the crushing chamber, where the gyrating head applies pressure against the concave liners.

- Discharge Opening: Once the material is crushed to the desired size, it exits through the discharge opening at the bottom of the crusher.

Advantages of a Gyratory Crusher:

- High Capacity: Gyratory crushers are capable of handling a very large feed size and high capacity.

- Stable Operation: They tend to be more stable than cone crushers, especially in high-capacity, heavy-duty applications.

- Less Sensitive to Material Moisture Content: Gyratory crushers can handle wet and sticky material better than jaw crushers.

Applications:

Gyratory crushers are used primarily for primary crushing in large-scale mining operations and large aggregate plants.

It’s important to note that the choice between a gyratory crusher and other primary crushers (like jaw crushers) depends on factors such as feed size, desired product size, and production capacity requirements. Proper maintenance, including regular inspections and replacement of worn parts, is essential for optimal performance and longevity.

Cone Crusher

A cone crusher is a type of secondary crusher that is used to reduce large rocks into smaller pieces by compressing and crushing them between a rotating cone-shaped bowl and an outer concave surface. This machine is typically used after the primary crushing stage where the material has been reduced to a size that allows it to be further processed.

Here are the key components and workings of a typical cone crusher:

Components of a Cone Crusher:

- Mantle: The mantle is the fixed, outer surface of the cone crusher. It is typically made of manganese steel and is replaceable. The mantle is shaped like a cone and provides the crushing action by moving in and out against the concave.

- Concave Liner: The concave is the inner surface of the cone crusher that fits over the mantle. Like the mantle, it is also typically made of manganese steel and is replaceable. The concave is shaped to create a chamber that allows the material to be crushed.

- Main Shaft: The main shaft is the central vertical spindle that supports and transmits the rotating motion to the mantle.

- Eccentric Sleeve and Eccentric Bushing: The eccentric sleeve is a component that is attached to the main shaft. It houses the eccentric bearing, which allows the mantle to move in an eccentric motion. The eccentric bushing is positioned between the main shaft and the eccentric sleeve.

- Head Assembly: This assembly comprises the main shaft, mantle, and the head nut which is used to secure the mantle in place.

- Adjustment Ring: The adjustment ring is a threaded component that is used to adjust the gap between the mantle and concave, controlling the size of the crushed material.

- Tramp Release Assembly: Some cone crushers are equipped with a tramp release system that allows for uncrushable material to pass through the crusher without causing damage. This is particularly important for the protection of the crusher and its components.

- Dust Seal Ring: This ring is located between the mantle and the concave liners. It helps to prevent dust and contaminants from entering the crusher.

How a Cone Crusher Works:

- Feed Hopper: Material is fed into the crusher through a hopper. The size of the material can vary, depending on the specific application.

- Crushing Chamber: The material enters the crushing chamber, where the rotating mantle applies pressure against the stationary concave, crushing the material.

- Discharge Opening: Once the material reaches the desired size, it exits through the discharge opening at the bottom of the crusher.

Advantages of a Cone Crusher:

- Uniform Particle Size: Cone crushers produce more uniform-sized end products compared to jaw or impact crushers.

- Versatility: They can handle a wide range of materials, from soft to hard and from dry to wet.

- Stable Operation: Cone crushers are generally more stable than other types of crushers.

Applications:

Cone crushers are commonly used in the secondary and tertiary stages of crushing in quarrying, mining, and aggregate production operations.

Proper maintenance, including regular inspections and replacement of worn parts, is essential for optimal performance and longevity.

Impact Crusher

An impact crusher is a machine used for crushing large rocks, gravel, or stones into smaller pieces. It employs a high-speed rotor with hammers or blow bars that impact the material and cause it to break apart. Impact crushers are particularly effective for producing cubical-shaped products and are commonly used in the mining, construction, and recycling industries.

Here are the key components and workings of a typical impact crusher:

Components of an Impact Crusher:

- Rotor: The rotor is the rotating part of the crusher that carries the hammers or blowbars. It’s responsible for generating the kinetic energy needed to crush the material.

- Hammers or Blow Bars: These are the striking tools attached to the rotor. They come in various shapes and materials, and they’re the primary means by which the impact crusher breaks down the material.

- Breaker Plates: These are fixed plates located on both sides of the crushing chamber. They help control the size of the crushed material and protect the crusher’s housing.

- Feed Chute: Material enters the crusher through the feed chute and is directed into the crushing chamber.

- Impact Curtains or Crushing Chamber: This is the space where the material undergoes impact and crushing. It’s typically lined with wear-resistant materials to prolong the life of the chamber.

- Adjustment System: Some impact crushers come with an adjustment system that allows the operator to adjust the gap between the impact curtains and rotor to control the size of the crushed material.

- Apron and Chain Curtain: Some impact crushers are equipped with an apron that prevents oversized material from escaping the crusher. This material is then directed back into the crushing chamber for further reduction.

- Rotor Support Bearings: These bearings support the rotor’s weight and allow it to rotate freely.

How an Impact Crusher Works:

- Feed Material: Material is fed into the crusher through the feed chute.

- Impact of Hammers or Blow Bars: The rotor spins rapidly, causing the hammers or blowbars to strike the material. This impact breaks the material into smaller pieces.

- Crushed Material Exit: Once the material reaches the desired size, it exits through the bottom of the crusher.

Advantages of an Impact Crusher:

- Cubical-Shaped Product: Impact crushers are known for producing cubical-shaped end products, which is important for many applications, such as concrete production.

- High Reduction Ratio: They are capable of producing high reduction ratios, meaning they can crush larger-sized material effectively.

- Versatility: Impact crushers can handle a wide range of materials, from soft to hard and from dry to wet.

Applications:

Impact crushers are commonly used in the construction and mining industries for secondary or tertiary crushing. They’re also used in recycling applications to process concrete, asphalt, and demolition waste.

Proper maintenance, including regular inspections and replacement of worn parts, is essential for optimal performance and longevity.

Hammer Crusher

A hammer crusher, also known as a hammer mill, is a type of crushing machine used to shred or crush materials into smaller pieces. It operates on the principle of applying force in the form of repeated blows delivered by rapidly rotating hammers.

Here are the key components and workings of a typical hammer crusher:

Components of a Hammer Crusher:

- Rotor: The rotor is a heavy-duty, rotating drum or disc that carries the hammers. It spins at high speeds and is responsible for generating the kinetic energy required for the crushing process.

- Hammers: These are the striking tools attached to the rotor. They come in various shapes and sizes, depending on the specific application. The hammers deliver the impact force to the material, causing it to break apart.

- Crushing Chamber: This is the space enclosed by the rotor and the housing of the crusher. It contains the material being crushed.

- Feed Inlet: Material is fed into the crusher through the feed inlet, often with the assistance of a conveyor belt or gravity.

- Grid or Grate Bars: Some hammer crushers have a grid or set of grate bars at the bottom of the crushing chamber. These bars allow smaller-sized material to pass through while keeping larger pieces in the chamber for further crushing.

- Drive System: The rotor is powered by an electric motor, diesel engine, or other power source through a system of belts and pulleys.

How a Hammer Crusher Works:

- Material Feed: Material is fed into the crusher through the feed inlet.

- Impact of Hammers: The rotor spins rapidly, causing the hammers to strike the material. This repeated impact shatters the material into smaller pieces.

- Discharge of Crushed Material: Once the material reaches the desired size, it is expelled from the crusher through openings in the grid or grate bars (if present) at the bottom.

Advantages of a Hammer Crusher:

- High Reduction Ratio: Hammer crushers are capable of producing high reduction ratios, making them suitable for primary and secondary crushing.

- Versatility: They can handle a wide range of materials, including soft, medium-hard, and brittle substances.

- Low Maintenance: Hammer crushers are relatively simple in structure, which can lead to lower maintenance requirements compared to some other crushers.

Applications:

Hammer crushers are used in a variety of industries, including mining, construction, and recycling. They’re often employed for the reduction of limestone, gypsum, coal, and other similar materials.

It’s important to note that different types of hammers and grid configurations are available to suit specific applications. Regular maintenance, including inspection and replacement of worn parts, is crucial for ensuring optimal performance and longevity.

Roll Crusher

A roll crusher, also known as a double roll crusher, is a type of compression machine used to crush hard materials. It consists of two large metal rolls that rotate in opposite directions. The material is fed into the gap between the rolls and is crushed by the compressive forces exerted by the rotating rolls.

Here are the key components and workings of a typical roll crusher:

Components of a Roll Crusher:

- Two Rolls: These are the main components of the roll crusher. They are typically made of high-strength steel and can vary in size and diameter depending on the specific application.

- Roll Bearings: These are the bearings that support the rolls and allow them to rotate freely. They are typically heavy-duty, spherical roller bearings.

- Roll Shafts: These are the shafts that hold and rotate the rolls. They’re usually made of forged steel.

- Feed Material: Material is fed into the crusher through a hopper or chute.

- Adjustment Mechanism: Some roll crushers have an adjustment mechanism that allows the operator to change the gap between the rolls. This controls the size of the crushed material.

- Drive System: The rolls are driven by an electric motor, often through a system of belts and pulleys.

How a Roll Crusher Works:

- Material Feed: Material is fed into the crusher through the feed hopper or chute.

- Crushing Action: The rolls rotate towards each other, exerting a compressive force on the material. This force causes the material to be crushed and pass through the gap between the rolls.

- Discharge of Crushed Material: The crushed material exits the crusher through the bottom of the machine.

Advantages of a Roll Crusher:

- High Reduction Ratio: Roll crushers typically achieve a high reduction ratio. This means they can crush large-sized material effectively.

- Cubical Product: They tend to produce a more cubical product compared to some other types of crushers.

- Simple Design: Roll crushers are relatively simple in structure, which can lead to lower maintenance requirements.

Applications:

Roll crushers are used in a variety of industries, including mining, construction, and mineral processing. They are often employed for the reduction of coal, limestone, salt, and other similar materials.

Limitations:

- Not Suitable for Abrasive Materials: Roll crushers may not be suitable for processing very hard or abrasive materials, as they can experience wear and tear.

- Not Ideal for Fine Crushing: They are generally used for coarse and intermediate crushing rather than fine crushing.

Regular maintenance, including inspection and replacement of worn parts, is crucial for ensuring optimal performance and longevity.

Cage Mill Crusher

A cage mill crusher, also known as a cage mill, is a versatile machine that applies a high-speed rotary motion to crush materials into smaller sizes. It consists of a cylindrical steel housing with an internal spinning rotor equipped with hammers or blades. This design allows the cage mill to deliver controlled, uniform crushing of a wide range of materials.

Here are the key components and workings of a typical cage mill crusher:

Components of a Cage Mill Crusher:

- Rotor: The rotor is a central component, usually cylindrical in shape, that contains the rotating hammers or blades. It is mounted on a shaft within the housing.

- Hammers or Blades: These are the striking tools attached to the rotor. They come in various shapes and sizes, depending on the specific application. The hammers impact the material to initiate the crushing process.

- Housing: The housing is a cylindrical steel shell that encases the rotor. It contains openings or screens through which the crushed material is discharged.

- Feed Inlet: Material is fed into the crusher through the feed inlet, typically located at the top of the housing.

- Screens or Grids: Some cage mills are equipped with screens or grids, located at the bottom of the housing. These screens control the size of the crushed material and allow it to exit the crusher.

How a Cage Mill Crusher Works:

- Material Feed: Material is fed into the crusher through the feed inlet.

- Impact of Hammers: The rotor spins rapidly, causing the hammers or blades to strike the material. This impact breaks the material into smaller pieces.

- Discharge of Crushed Material: Once the material reaches the desired size, it exits the crusher through the screens or grids at the bottom.

Advantages of a Cage Mill Crusher:

- Uniform Particle Size: Cage mills are known for producing consistently sized end products, which is crucial for many applications, such as in the production of agricultural materials.

- Versatility: They can handle a wide range of materials, from soft to moderately hard.

- Low Maintenance: Cage mills are relatively simple in structure, which can lead to lower maintenance requirements compared to some other crushers.

Applications:

Cage mill crushers are used in various industries, including agriculture, mining, recycling, and chemical processing. They’re often employed for the reduction of fertilizers, potash, limestone, and other similar materials.

It’s important to note that different types of hammers and screen configurations are available to suit specific applications. Regular maintenance, including inspection and replacement of worn parts, is crucial for ensuring optimal performance and longevity.

Vertical Shaft Impactor (VSI)

A Vertical Shaft Impactor (VSI), also known as a vertical shaft impact crusher, is a type of crusher used in the mining and aggregate industries for shaping and producing high-quality cubical aggregates. It operates by accelerating material into a rock-lined rotor where it is ejected out, creating a rock-on-rock impact.

Here are the key components and workings of a typical Vertical Shaft Impactor:

Components of a Vertical Shaft Impactor (VSI):

- Rotor: The rotor is a cylindrical metal component with several wear-resistant, hardened steel bars or shoes attached to it. It spins at high speeds and is responsible for generating the kinetic energy needed for the crushing process.

- Feed Tube: This is a vertical tube through which material is fed into the rotor. It’s designed to ensure a controlled and consistent flow of material.

- Anvil Rings or Rock Shelves: These are stationary metal structures located within the crushing chamber. They serve as the impact surface against which the material is crushed.

- Lid and Housing: The lid is the top cover of the crusher, and the housing encases the rotor and other internal components. They’re typically made of sturdy steel to withstand the forces generated during operation.

- Feed Inlet: Material is fed into the crusher through the feed tube, typically located at the top.

- Drive System: The rotor is powered by an electric motor, often through a system of belts and pulleys.

How a Vertical Shaft Impactor (VSI) Works:

- Material Feed: Material is fed into the crusher through the feed tube.

- Acceleration of Material: The rotor spins rapidly, flinging the material against the anvil rings or rock shelves. This high-speed impact causes the material to break apart.

- Crushed Material Exit: Once the material reaches the desired size, it is expelled from the crusher.

Advantages of a Vertical Shaft Impactor (VSI):

- Cubical-Shaped Product: VSI crushers are known for producing cubical-shaped end products, which is important for many applications, such as in the production of concrete and asphalt.

- High Reduction Ratio: They are capable of producing high reduction ratios, meaning they can crush larger-sized material effectively.

- Selective Crushing: VSI crushers allow for selective crushing of material, which means that certain types of material can be processed more efficiently than others.

Applications:

Vertical Shaft Impactors are commonly used in the production of high-quality aggregates, particularly for the construction and mining industries. They are also used in the production of manufactured sand and in recycling applications.

Regular maintenance, including inspection and replacement of worn parts, is crucial for ensuring optimal performance and longevity.

Horizontal Shaft Impactor (HSI)

A Horizontal Shaft Impactor (HSI) is a type of crusher that uses a horizontal shaft to crush material into smaller pieces. It’s widely used in the mining, construction, and recycling industries for primary and secondary crushing. Unlike Vertical Shaft Impactors (VSI), which use a vertical shaft, HSIs operate by impacting the material with hammers or blow bars attached to the rotor.

Here are the key components and workings of a typical Horizontal Shaft Impactor:

Components of a Horizontal Shaft Impactor (HSI):

- Rotor: The rotor is a horizontal shaft with a series of hammers or blow bars attached to it. It rotates at high speeds and is responsible for generating the kinetic energy needed for the crushing process.

- Hammers or Blow Bars: These are the striking tools attached to the rotor. They come in various shapes and sizes, depending on the specific application. The hammers impact the material to initiate the crushing process.

- Crushing Chamber: This is the space enclosed by the rotor and the housing of the crusher. It contains the material being crushed.

- Feed Inlet: Material is fed into the crusher through the feed inlet, typically located at the top of the housing.

- Adjustment Mechanism: Some HSIs have an adjustment mechanism that allows the operator to change the gap between the hammers or blow bars and the impact plates. This controls the size of the crushed material.

- Apron and Impact Plates: Some HSIs are equipped with an apron that prevents oversized material from escaping the crusher. This material is then directed back into the crushing chamber for further reduction. Impact plates, also known as breaker plates, are wear-resistant plates that line the crushing chamber.

How a Horizontal Shaft Impactor (HSI) Works:

- Material Feed: Material is fed into the crusher through the feed inlet.

- Impact of Hammers or Blow Bars: The rotor spins rapidly, causing the hammers or blowbars to strike the material. This impact breaks the material into smaller pieces.

- Discharge of Crushed Material: Once the material reaches the desired size, it exits the crusher through the bottom or sides.

Advantages of a Horizontal Shaft Impactor (HSI):

- Cubical-Shaped Product: HSIs are known for producing cubical-shaped end products, which are important for many applications, such as in the production of concrete and asphalt.

- High Reduction Ratio: They are capable of producing high reduction ratios, meaning they can crush larger-sized material effectively.

- Versatility: HSIs can handle a wide range of materials, from soft to moderately hard.

Applications:

Horizontal Shaft Impactors are commonly used in the production of high-quality aggregates for the construction and mining industries. They are also used in recycling applications to process concrete, asphalt, and demolition waste.

Regular maintenance, including inspection and replacement of worn parts, is crucial for ensuring optimal performance and longevity.

Cone Crusher with Inclined Screen

A cone crusher with an inclined screen is a versatile crushing and screening machine that combines the capabilities of a traditional cone crusher with the added functionality of a vibrating screen. This configuration allows for the production of multiple sizes of material in a single pass, making it a valuable tool in aggregate production and mining operations.

Here are the key components and workings of a typical cone crusher with an inclined screen:

Components of a Cone Crusher with Inclined Screen:

- Cone Crusher: The cone crusher component remains similar to a standard cone crusher. It includes a rotating mantle and a stationary concave, allowing for the compression and crushing of material.

- Inclined Screen: Positioned above the cone crusher, the inclined screen is equipped with multiple decks and screens that vibrate to separate and classify material into different sizes. The inclination of the screen aids in the screening process.

- Feed Hopper: Material is loaded into the crusher through a feed hopper. The size of the material can vary, depending on the specific application.

- Conveyor Belts: In some configurations, conveyors are used to transport material to and from the crusher and screen.

- Adjustment Mechanism: Some cone crushers with screens have an adjustment mechanism that allows the operator to control the size of the crushed material and the screened product.

- Control Panel: This component houses the controls and interface for operating and monitoring the cone crusher and inclined screen.

How a Cone Crusher with Inclined Screen Works:

- Material Feed: Material is loaded into the crusher through the feed hopper.

- Cone Crusher Operation: The material undergoes compression and crushing as it passes through the cone crusher.

- Screening Process: After being crushed, the material is conveyed onto the inclined screen, where it is separated into different sizes. The vibrating motion of the screen decks aids in this process.

- Sorted Product: The screened products of various sizes exit through different outlets, typically onto separate conveyors for further processing or stockpiling.

Advantages of a Cone Crusher with Inclined Screen:

- Multi-Size Output: This configuration allows for the production of multiple sizes of material in a single pass, reducing the need for additional screening equipment.

- Efficient Screening: The inclined screen efficiently separates material into different sizes, enhancing the quality of the final product.

- Space and Cost Efficiency: Combining crushing and screening functions in one machine can save space and reduce the need for additional equipment.

Applications:

Cone crushers with inclined screens are used in a variety of industries, including aggregate production, mining, and construction. They are particularly useful in applications where a range of different-sized products is required.

Regular maintenance, including inspection and replacement of worn parts, is crucial for ensuring optimal performance and longevity. Additionally, ensuring the proper operation of the screen and addressing any maintenance needs promptly is essential for efficient screening.

Discover more from AllMinings

Subscribe to get the latest posts sent to your email.