Primary crushing in the mining industry refers to the initial stage of reducing large rocks or ore into smaller pieces. This is typically done using mechanical equipment such as jaw crushers or gyratory crushers. The goal of primary crushing is to facilitate the next stages of processing, such as secondary crushing, milling, or leaching, by preparing the material to be more easily handled and processed. Here’s a concise example of a list highlighting key aspects of the primary crushing process in a mining operation:

Critical Commencement

“Critical Commencement” refers to the pivotal starting point of a process or operation that holds significant importance in its overall success or outcome. It marks the initiation or inception of a procedure or endeavour that plays a crucial role in achieving desired results.

In the context of primary crushing in mining operations, “Critical Commencement” underscores the fundamental significance of this initial step. It signifies the beginning of the process where large, raw materials are broken down into manageable sizes, setting the stage for subsequent stages of processing. This phase is essential in ensuring that the extracted materials are appropriately sized for further refinement and extraction of valuable minerals or ores.

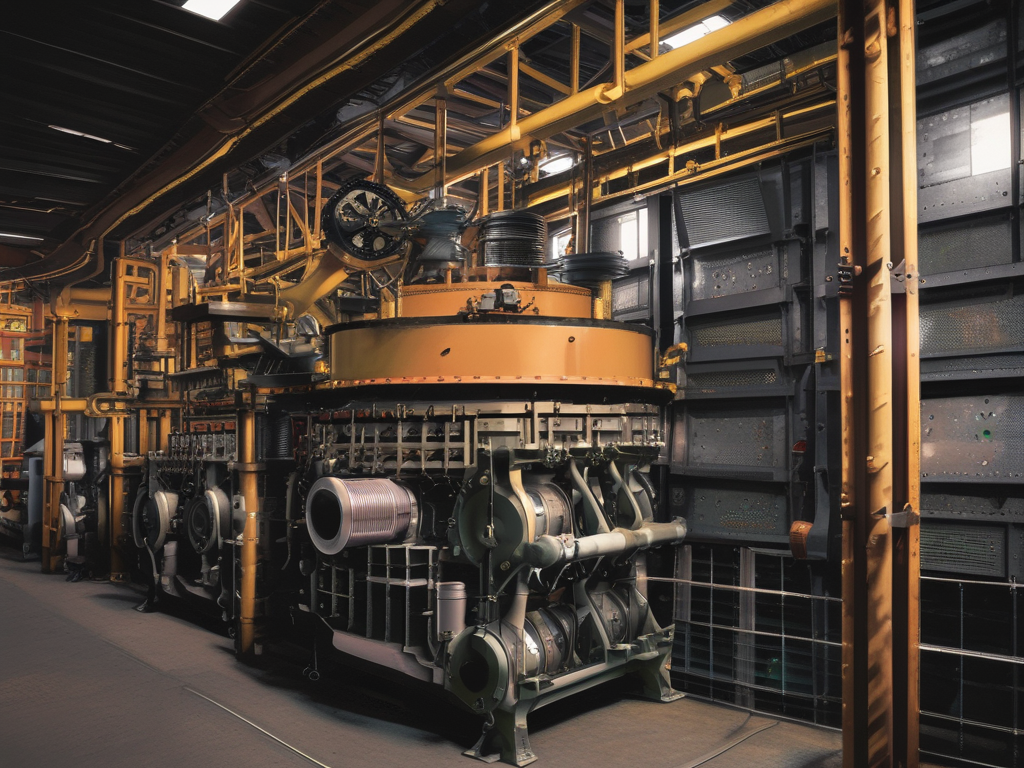

Equipment Pinnacle: Jaw Crusher or Gyratory Crusher

“Equipment Pinnacle: Jaw Crusher or Gyratory Crusher” emphasizes the paramount importance of selecting the right primary crushing equipment in mining operations. It presents a choice between two of the most commonly used machines for this purpose, each with its distinct characteristics and advantages.

- Jaw Crusher: This stalwart machine exerts direct pressure on the material, effectively compressing it between two rigid surfaces. It is known for its simplicity, ruggedness, and versatility, making it suitable for a wide range of materials and applications.

- Gyratory Crusher: This equipment employs a gyrating motion, where a conical head revolves within an outer concave bowl. This motion compresses the material against the concave, producing finer output. Gyratory crushers are often preferred for their higher capacity and finer reduction ratios.

The choice between a jaw crusher and a gyratory crusher depends on various factors, including the type of material, desired output size, capacity requirements, and operational considerations specific to the mining site. Both machines have their strengths and are selected based on the unique characteristics of the material being processed and the operational goals of the mining operation.

Material Influx

“Material Influx” refers to the introduction or arrival of raw materials into a designated processing area or equipment. In the context of mining operations, material influx is a critical phase in the primary crushing process.

In the primary crushing stage, large rocks or ore are introduced into the crusher for further processing. This can be accomplished through various means, such as using a vibrating grizzly feeder that regulates the flow of material or by direct loading from trucks or loaders.

Efficient material influx is essential for maintaining a steady and controlled feed rate to the crusher, ensuring that the equipment operates optimally and that the material is processed effectively. Proper regulation of material influx is a crucial aspect of achieving consistent and reliable results in the primary crushing process.

Relentless Crushing Force

“Relentless Crushing Force” evokes the powerful and continuous pressure applied to raw materials during the primary crushing process in mining operations. This phrase underscores the sheer intensity and determination with which the crushing equipment, such as jaw crushers or gyratory crushers, exerts pressure to break down large rocks or ore into smaller, manageable pieces.

In a jaw crusher, for instance, the material is subjected to intense compression between two rigid surfaces, while in a gyratory crusher, the material experiences the relentless force of a rotating head against a stationary concave. This unyielding pressure is essential for effectively reducing the size of the material and preparing it for subsequent processing stages.

“Relentless Crushing Force” encapsulates the dynamic and robust nature of the primary crushing operation, highlighting its critical role in preparing raw materials for further extraction and refinement in the mining process.

Converging on Size

“Converging on Size” describes the process by which raw materials, subjected to intense pressure and force in a primary crusher, steadily reduce in size until they reach the desired dimensions for downstream processing.

In a jaw crusher, for example, large rocks or ore are initially too large to meet the specifications required for further stages. As the crushing mechanism exerts its force, the material gradually converges or narrows in size, moving closer to the target dimensions.

Similarly, in a gyratory crusher, the gyrating motion of the head and the compression against the stationary concave facilitate the convergence of the material towards the desired size.

“Converging on Size” emphasizes the purposeful reduction process that is central to primary crushing, ensuring that the extracted material is appropriately sized for subsequent stages of processing in the mining operation.

Sizing Departure

“Sizing Departure” denotes the moment when raw materials, having undergone primary crushing, achieve the desired dimensions for further processing in a mining operation. It marks the departure from the initial, larger form of the material to the specified size required for subsequent stages.

This phase is crucial in ensuring that the material is appropriately prepared for the next steps in the mining process, such as secondary crushing, milling, or leaching. Achieving the correct size through primary crushing is fundamental to efficient and effective mineral extraction.

Dimensional Destiny

“Dimensional Destiny” embodies the strategic culmination of primary crushing in mining operations. It represents the moment when raw materials, having endured intense pressure and force, attain the precise dimensions mandated for subsequent processing stages.

In this pivotal juncture, oversized rocks or ore fragments find their purpose, their contours meticulously sculpted to align with the operational and product specifications of the mining venture. This attainment of the desired dimensions is the fulcrum upon which the entire mining process hinges.

“Dimensional Destiny” encapsulates the meticulous engineering and precision required in primary crushing, highlighting its instrumental role in shaping raw materials into a form ready for the ensuing stages of refinement and extraction in the mining operation.

Capacity Crest

“Capacity Crest” signifies the zenith of capability that a primary crusher must possess in a mining operation. It represents the maximum volume of material that the crusher is designed to handle efficiently and effectively.

The primary crusher’s capacity is a critical factor in ensuring that the anticipated volume of raw material extracted from the mine can be processed without overwhelming the equipment. It sets the upper limit on the throughput, influencing the overall productivity and efficiency of the mining operation.

Selecting a primary crusher with an appropriate capacity crest is essential for maintaining a smooth and uninterrupted flow of material through the processing stages, ultimately contributing to the success and profitability of the mining venture.

Maintenance Mandate

“Maintenance Mandate” underscores the imperative nature of regular and systematic upkeep in the operation of primary crushers within the mining industry. It represents the inherent responsibility to conduct scheduled maintenance tasks to ensure the equipment’s optimal performance and longevity.

This mandate encompasses a range of activities, including but not limited to lubrication, inspection, and replacement of worn components. Adhering to a rigorous maintenance schedule not only prolongs the lifespan of the primary crusher but also contributes to the safety and efficiency of the overall mining operation.

The “Maintenance Mandate” is a cornerstone of responsible mining practices, safeguarding both equipment investment and the well-being of personnel involved in the operation. It is a fundamental commitment to operational excellence and sustainable resource extraction.

Safety Summit

“Safety Summit” stands as the paramount priority in any mining operation, particularly during the primary crushing process. It signifies the collective effort and dedication invested in ensuring the well-being and security of all personnel working close to the primary crusher.

A Safety Summit encompasses a comprehensive approach to safety, incorporating measures such as the implementation of protective guards, adherence to established safety protocols, and the deployment of advanced alert systems. These measures collectively create a secure environment, minimizing risks and potential hazards associated with the primary crushing phase.

By establishing a Safety Summit, mining operations prioritize the welfare of their workforce and affirm their commitment to responsible and sustainable resource extraction. It serves as a cornerstone in fostering a culture of safety and accountability within the mining industry.

Discover more from AllMinings

Subscribe to get the latest posts sent to your email.