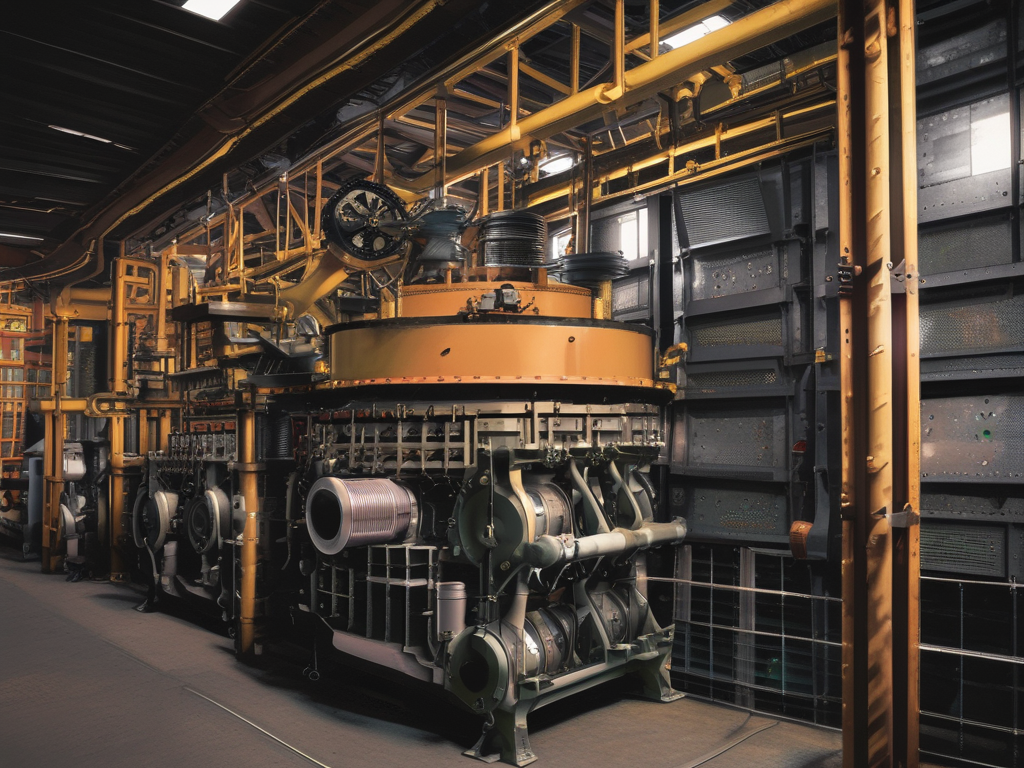

Secondary crushing is an essential process in the mineral processing industry. It involves reducing the size of the ore from a primary crushing stage to a finer particle size that can be further processed. Here is an overview of secondary crushing in mineral processing:

Purpose

The purpose of secondary crushing in mineral processing is to reduce the size of ore from the primary crushing stage to a finer particle size, facilitating easier handling and further processing. This size reduction enhances the overall efficiency of the mineral processing plant by ensuring the material is suitable for downstream processes such as grinding and beneficiation. Secondary crushing increases the exposure of valuable minerals within the ore, improving the effectiveness of subsequent separation and extraction processes. It produces a consistent and uniform particle size distribution, which is crucial for the efficiency of these downstream processes. Additionally, secondary crushing helps lower the energy requirements for grinding operations, thereby reducing operational costs and wear on grinding equipment. By ensuring the material is properly prepared for processes like flotation, magnetic separation, or leaching, secondary crushing plays a key role in optimizing the plant’s capacity, increasing throughput, and improving the quality and consistency of the final product.

Types of Secondary Crushers

Cone crushers utilize a rotating cone within a stationary concave to crush the ore and are ideal for hard, abrasive materials. They are commonly used in secondary crushing stages due to their high efficiency, good reduction ratios, and ability to produce a well-shaped final product. Impact crushers employ impact force to break the material, which is fed into the crushing chamber and struck by high-speed blow bars or hammers. Suitable for softer, less abrasive materials, impact crushers are often used in the secondary stage for materials like limestone, providing high reduction ratios and a uniform particle shape.

Hammer mills operate by using hammers fixed to a spinning rotor to crush the ore against a stationary anvil, effective for softer materials and used in both secondary and tertiary crushing stages. They offer high reduction ratios, high throughput, and the ability to handle a variety of materials. Roll crushers compress the material between two rotating rolls, best suited for medium to hard materials, and are used in secondary crushing stages where minimal fines production is desired. Roll crushers produce uniform particle size, low dust and fines generation, and are efficient for medium hardness materials.

Gyratory crushers are similar to cone crushers but have a steeper crushing chamber and a gyrating spindle. They are used for secondary crushing of very hard and abrasive materials, offering high throughput capacity, and capable of producing a relatively uniform particle size. Jaw crushers, typically used in primary crushing, can also be used in secondary crushing applications where high reduction ratios are needed. They crush material by compressing it between a stationary jaw and a moving jaw, providing a simple structure, reliable operation, and the ability to handle various materials.

Each type of secondary crusher is selected based on specific processing plant requirements, including the material’s characteristics, the desired product size, and the necessary production capacity.

Key Considerations

The key considerations in secondary crushing revolve around ensuring that the process is efficient and effective in reducing the ore size while maintaining the quality of the final product. The type and characteristics of the feed material play a crucial role, as the nature of the ore and its size from the primary crushing stage determine the appropriate type of secondary crusher to be used. Capacity requirements must align with production needs to ensure the secondary crusher can handle the necessary throughput without becoming a bottleneck.

The desired product size is another critical factor, influencing the choice of crusher and the settings used. Achieving a consistent and uniform particle size is essential for the efficiency of downstream processes. Material hardness and abrasiveness affect the wear and tear on the crusher, impacting maintenance costs and downtime. Therefore, selecting a crusher that can handle the material’s properties is vital for longevity and cost-effectiveness.

The reduction ratio, which is the ratio between the size of the feed and the size of the output, is important in determining the number of crushing stages needed. A high reduction ratio might reduce the need for additional crushing stages, optimizing the process. Ensuring the crusher’s capacity matches the plant’s production requirements is crucial to prevent underperformance or overloading, which can lead to inefficiencies and increased operational costs.

Regular maintenance is essential to prevent unexpected downtime and extend the lifespan of the equipment. Automation and control systems can optimize the crushing process, improving efficiency and ensuring consistent performance. Enhancing material handling systems to improve flow rates and reduce bottlenecks can also contribute to a more efficient secondary crushing stage. Overall, these considerations help in selecting the appropriate equipment and optimizing the secondary crushing process to achieve desired outcomes in mineral processing.

Integration in Processing Plant

Secondary crushing is integrated into a mineral processing plant as a crucial intermediate step that follows primary crushing and precedes grinding and beneficiation stages. Its role is to reduce the size of the material further, preparing it for efficient processing in subsequent stages.

The integration begins with material being fed from the primary crusher into the secondary crusher via conveyors or feeders. The choice of secondary crusher is aligned with the characteristics of the material from the primary crushing stage, ensuring that the crusher can handle the size and hardness of the feed. This step ensures that the material is reduced to a size suitable for the grinding process, typically conducted in mills.

A well-designed screening system is often integrated with secondary crushing to classify the crushed material by size. This screening system can include vibratory screens that separate fine and coarse particles, ensuring that only material of the desired size proceeds to the grinding stage. Oversized material from the screens may be recirculated back to the secondary crusher for further reduction, creating a closed-loop system that enhances efficiency.

The material handling systems, such as conveyors and hoppers, are designed to minimize spillage, dust generation, and degradation of the material. Effective dust control measures, such as dust suppression systems, are critical to maintaining a safe and clean working environment.

Automation and control systems play a significant role in the integration of secondary crushing. These systems can monitor and adjust the crushing process in real-time, optimizing crusher performance and ensuring consistent output quality. Advanced control systems can adjust crusher settings, feed rates, and monitor wear to maximize efficiency and minimize downtime.

Safety mechanisms are also integrated into the secondary crushing stage to protect operators and equipment. These may include emergency stop buttons, safety guards, and automatic shutdown features in case of equipment failure or overload.

Secondary crushing, as part of a larger circuit that includes primary crushing, screening, conveying, and grinding, ensures that the material is properly prepared for each subsequent stage. This integration enhances the overall efficiency of the mineral processing plant, ensuring that the throughput is maximized, and the quality of the final product is maintained. The design and operation of the secondary crushing stage are tailored to fit seamlessly into the overall plant flow, achieving a balanced and optimized processing system.

Advantages

The integration of secondary crushing into a processing plant offers several advantages:

Efficiency: Secondary crushing ensures that the ore is reduced to a suitable size for downstream processes like grinding and beneficiation, improving overall plant efficiency.

Productivity: By reducing the size of the ore early in the process, secondary crushing increases throughput and optimizes the utilization of downstream equipment.

Cost-effectiveness: Properly sized ore from secondary crushing reduces energy consumption in subsequent grinding operations, lowering operational costs.

Improved product quality: Secondary crushing produces a more uniform particle size distribution, enhancing the consistency and quality of the final product.

Enhanced liberation: Breaking the ore into finer particles exposes more surface area of valuable minerals, facilitating better extraction during subsequent processes.

Flexibility: Different types of secondary crushers can be selected based on ore characteristics and processing requirements, providing flexibility in plant design and operation.

Reduced wear and maintenance: Well-chosen secondary crushers experience less wear and require fewer maintenance interventions, contributing to longer equipment life and reduced downtime.

Environmental benefits: Effective secondary crushing systems can include dust control measures, minimizing environmental impact and improving workplace safety.

Process optimization: Integrated control systems can optimize crusher performance and adjust operational parameters in real-time, maximizing efficiency and throughput.

Safety: Safety features integrated into secondary crushing equipment protect operators and ensure compliance with safety regulations, maintaining a secure work environment.

Challenges

Challenges associated with secondary crushing in mineral processing include:

Operational complexity: Integrating secondary crushers into a processing plant requires careful planning and design to ensure smooth operation and efficient material flow.

Material variability: The characteristics of ore can vary widely, affecting the performance and efficiency of secondary crushers. Abrasive and hard materials may cause increased wear on equipment.

Maintenance requirements: Secondary crushers require regular maintenance to optimize performance and prevent unplanned downtime. Wear parts replacement and equipment inspections are critical to maintaining productivity.

Energy consumption: Secondary crushing operations can be energy-intensive, particularly if not optimized for efficiency. Managing energy use and minimizing operational costs are ongoing challenges.

Particle size distribution: Achieving a consistent and desired particle size distribution from secondary crushing can be challenging, impacting downstream processes like grinding and beneficiation.

Dust and environmental impact: Crushing operations generate dust and noise, requiring effective dust suppression systems and environmental management practices to mitigate impact on air quality and surroundings.

Process optimization: Balancing throughput, product quality, and energy efficiency requires ongoing process optimization and adjustment of operational parameters.

Safety hazards: Working around secondary crushing equipment poses safety risks due to moving parts, high energy levels, and potential exposure to dust and noise. Proper safety protocols and equipment guarding are essential.

Integration with upstream and downstream processes: Ensuring seamless integration with primary crushing, screening, and subsequent processing stages requires coordination and alignment of equipment and material flows.

Regulatory compliance: Meeting environmental and safety regulations related to secondary crushing operations requires adherence to standards for emissions, noise levels, and workplace safety.

Optimization Strategies

Optimization strategies for secondary crushing in mineral processing involve:

Continuous monitoring: Implementing real-time monitoring systems to track crusher performance, feed rates, and particle size distribution, allowing for immediate adjustments.

Automation: Utilizing automated controls to optimize crusher settings and maintain consistent operation, reducing variability and improving efficiency.

Maintenance planning: Developing comprehensive maintenance schedules and procedures to minimize downtime and extend equipment life, including regular inspections and timely parts replacements.

Material handling improvements: Enhancing conveyor systems and material flow designs to reduce bottlenecks, optimize throughput, and ensure consistent feed to the crusher.

Energy efficiency initiatives: Implementing energy-saving technologies and practices, such as variable frequency drives (VFDs) and energy recovery systems, to minimize power consumption during crushing operations.

Particle size control: Implementing effective screening and classification systems to ensure the desired particle size distribution, optimizing downstream processes like grinding and flotation.

Training and skills development: Providing training programs for operators and maintenance personnel to enhance their skills in operating and maintaining secondary crushing equipment effectively.

Process integration: Optimizing the integration of secondary crushing with upstream and downstream processes, ensuring seamless material flow and maximizing overall plant efficiency.

Environmental management: Implementing dust suppression systems and environmental controls to minimize emissions and mitigate the impact of crushing operations on air quality and surroundings.

Data analytics: Utilizing data analytics and modeling techniques to analyze crusher performance trends, identify opportunities for improvement, and optimize operational parameters for maximum efficiency.

Safety Considerations

Safety considerations in secondary crushing operations include:

- Equipment Guarding: Ensuring all moving parts of the crusher are adequately guarded to prevent accidental contact and injuries.

- Emergency Stop Systems: Installing emergency stop buttons and pull cords within easy reach of operators to quickly halt operations in case of emergencies.

- Lockout/Tagout Procedures: Implementing lockout/tagout procedures during maintenance activities to prevent inadvertent startup of equipment.

- Noise and Vibration Control: Implementing measures to reduce noise levels and vibrations generated by crushing operations to protect worker hearing and comfort.

- Dust Control: Using effective dust suppression systems to minimize airborne dust particles, protecting workers from respiratory issues and improving air quality.

- Personal Protective Equipment (PPE): Providing appropriate PPE such as safety glasses, hearing protection, and respiratory protection to workers based on job tasks and exposure risks.

- Training and Awareness: Conducting regular safety training sessions for all personnel involved in operating, maintaining, and servicing secondary crushers to ensure they are aware of hazards and safety protocols.

- Maintenance Safety: Establishing safe work procedures for maintenance activities, including proper isolation of equipment, use of safety harnesses when working at heights, and adherence to confined space entry protocols.

- Risk Assessments: Conducting regular risk assessments to identify potential hazards associated with secondary crushing operations and implementing controls to mitigate risks.

- Emergency Response Planning: Developing and practicing emergency response plans to handle incidents such as equipment failures, fires, or injuries effectively and promptly.

These safety considerations aim to create a safe working environment for personnel involved in secondary crushing operations, mitigating risks and ensuring compliance with safety regulations and standards.

Environmental Impact

The environmental impact of secondary crushing in mineral processing includes several key considerations:

- Dust Emissions: Crushing operations can generate significant dust, particularly when handling dry or finely crushed materials. Dust emissions can contribute to air pollution and affect local air quality. Implementing effective dust suppression systems, such as misting or dust collection systems, helps mitigate these impacts.

- Noise Pollution: Crushing equipment can produce substantial noise levels, which may impact nearby communities and wildlife. Employing noise control measures, such as sound walls or acoustic enclosures, can help reduce noise propagation and minimize disturbances.

- Energy Consumption: Secondary crushing operations can be energy-intensive, particularly if crushers are not optimized for efficiency. Minimizing energy consumption through equipment selection, process optimization, and energy-efficient technologies contributes to reducing environmental footprint.

- Waste Generation: Secondary crushing may generate waste materials such as fines or reject material. Proper management of these wastes, including recycling or reuse where possible, helps minimize environmental impact.

- Water Usage: Some crushing operations require water for dust suppression or to control material flow. Managing water usage and ensuring proper containment and treatment of wastewater are essential to prevent contamination of water sources.

- Land Use and Habitat Disruption: Large-scale crushing operations can require significant land area, potentially impacting natural habitats and ecosystems. Conducting environmental impact assessments (EIAs) and adhering to regulatory requirements help mitigate potential habitat disruption and land use conflicts.

- Climate Change: Energy consumption and emissions associated with crushing operations contribute to greenhouse gas (GHG) emissions and climate change. Implementing energy-efficient practices and exploring renewable energy sources can help reduce carbon footprint.

- Regulatory Compliance: Compliance with environmental regulations and permits is crucial to minimizing environmental impact. This includes adherence to emission standards, noise limits, and environmental management practices.

- Biodiversity Conservation: Crushing operations may affect local biodiversity by disrupting habitats and ecosystems. Implementing biodiversity conservation measures, such as habitat restoration and wildlife management plans, helps mitigate these impacts.

- Sustainability Practices: Adopting sustainable practices in crushing operations, such as resource efficiency, waste reduction, and responsible sourcing of materials, promotes environmental stewardship and supports long-term sustainability.

Overall, addressing these environmental considerations through proactive management, technology adoption, and regulatory compliance is essential to minimizing the environmental impact of secondary crushing operations in mineral processing.

Future Trends

Future trends in secondary crushing within mineral processing are likely to focus on several key areas:

- Advanced Automation and Control: Increasing integration of automation systems and artificial intelligence (AI) to optimize crusher performance, adjust settings in real-time, and predict maintenance needs. This trend enhances efficiency, reduces downtime, and improves overall process reliability.

- Energy Efficiency: Continued emphasis on energy-efficient crushing technologies and practices to minimize power consumption and operational costs. This includes the adoption of energy recovery systems and advanced crushing technologies.

- Sustainability: Growing importance of sustainability in mineral processing, leading to the development of crushers and processes that reduce environmental impact. This includes innovations in dust and noise reduction, water recycling, and reduced emissions.

- Digitalization and Data Analytics: Utilization of big data analytics and digital twin technologies to model and optimize crushing processes. Predictive analytics will play a crucial role in improving equipment reliability, optimizing throughput, and reducing maintenance costs.

- Modular and Mobile Solutions: Increasing demand for modular and mobile crushing solutions that offer flexibility, rapid deployment, and scalability. These solutions cater to varying production needs and reduce construction and operational timelines.

- Sensor Technology and IoT: Integration of sensor technology and Internet of Things (IoT) devices for condition monitoring and real-time performance monitoring of crushers. This trend enhances predictive maintenance capabilities and improves equipment reliability.

- Material Science Innovations: Advancements in material science for crusher components to enhance wear resistance, durability, and performance. This includes the development of novel alloys and composite materials.

- Circular Economy Initiatives: Adoption of circular economy principles in mineral processing, promoting the recycling and reuse of materials and waste streams generated from crushing operations.

- Hybrid and Electric Crushers: Exploration of hybrid and electric-powered crushers to reduce carbon emissions and dependency on fossil fuels. These technologies contribute to sustainability goals and regulatory compliance.

- Safety and Ergonomics: Continued focus on improving safety features, ergonomics, and operator comfort in crushing equipment design. This includes innovations in noise reduction, vibration control, and ergonomic operator interfaces.

These future trends indicate a shift towards more efficient, sustainable, and technologically advanced secondary crushing solutions in mineral processing, driven by the need for improved productivity, reduced environmental impact, and enhanced operational safety.

Discover more from AllMinings

Subscribe to get the latest posts sent to your email.